HOME WELCOME SEVEN ELAN ELISE MIDGET TYPE R MINI LAND ROVER FAMILY MG TC GUEST BOOK

March April May June July August September October November December January February March April May June Tech. Index Gallery

(the months are 2015/2016)

The French Blatting Company

1949 MG TC

June 2015

1st June 2015

Spent the first hour looking for the missing shims from Roger Furneaux's package with the diff parts. Cannot find it so have asked if he can send another pair. Then searched the net for a simple web page creator in HTML. Found one, resized all the pictures on May's page, and uploaded it. Went to do June (this one) and it fell over. Downloaded it again and it still didn't work so then found this, PageBreeze, Seems OK but when I went to link a picture I got it wrong and deleting the little square it deleted everything on the page. Never mind, let's see how this looks without a picture. OK, that's good. Now let's try a picture (have you noticed it doesn't have a spill chicker)

.jpeg)

There you go, if you type the address in correctly it works. Wonderful. Now, let's find a spill chicker.

I've purchased the pro version, only 25€ so no big loss if it doesn't work. However I'm impressed that when I started it it read in the last page I'd been editing-this one.

I've spent the day stripping, cleaning and overhauling the carbs. I have finished one but can't find the float bolt to body bolt. I know it's amongst all the parts laid out on the blanket as it was with the float chamber which I took off when removing the engine but I cannot see it. I'll get another (and then find the original). The second carb is stripped and I've left it in a bowl of petrol overnight to loosen the gunge on it,

I came in at 1700, ordered the float chamber bolt and bought a University Motors dashboard plaque. The dash has a Vine & Lee plaque, the original selling dealers plaque, but as I started at UM 53 years ago (1961) and fitted these plaques to the MGA and Magnettes of the day I thought it made sense to fit one to my car.

.jpeg)

The Diff, completely assembled but missing the two shims. Roger should have them in the post tomorrow.

.jpeg)

The, hang on, got to work it out, (hangs head to the right, then to the left) Ah, OK, it's the left carb. In bits but cleaned. The bolt that holds the float chamber to the body is missing so I've ordered one from Moss Paris.

.jpeg)

The right hand carb before stripping and cleaning.

.jpeg)

Dirty? Well yes, and so would you be if you'd been left for 48 years in a dirty petrol and oil soaked environment.

.jpeg)

Now partially stripped I took the picture to remind me how the throttle attachments went.

This is the first page I've done with the new editor (not the man at the newspaper who hits the journalists on the head with a small hammer). It's called PageBreeze and I like it, simple to use, because I'm simple, very simple. :)

2nd June 2015

Started just after 0800 and finished the carbs. Don't they look nice? Then set up the sand blast kit and cleaned the shock absorbers. Stripped one down and pressed the shaft out (after marking it). Got the link arm bush out and pressed two new ones in then thought as I only have eight should it be one per link. Asked the TABC group and they confirm it is one per link. OK, no problem, I'll remove one and press the other into the centre. Have you noticed the text has gone into bold - and won't come out. Hope you like bold.

Note added on 16/06. I know what causes the bold print now but I'll leave it as is otherwise the text won't make sense-or I can't be bothered to change it.

.jpeg)

Nice and clean.

.jpeg)

And from the other side, their best side.

Overhauling the shock absorbers

.jpeg)

A very rusty and dirty shock absorber.

.jpeg)

Which has now been cleaned. Actualy it's not the same one, but who will notice.

.jpeg)

Another dirty one.

.jpeg)

And another clean one

.jpeg)

Four clean ones, OK enough! It's getting boring.

.jpeg)

The arm with two bushes, you can see the edges at each end. The arm has to be pushed into the bush. Not easy, but I have a cunning plan.

.jpeg)

The inside of the shocker. I'll take more detailed pictures of the next one I take apart, tomorrow.

We were going out tomorrow, to Le Mans to collect the tickets for the Saturday race day. However I have at least two deliveries coming so we've postponed Le Mans until Thursday.

3rd June 2015

Started at 0800 and carried on with the shock absorbers. My method of stripping and re-assembly is as follows.

1) Remove core plug by drilling a sequence of holes around the edge and one in the middle. Drive a (solid) screwdriver into one of the holes and prize out.

2) Undo end caps with a pair of stilsons. Undo the filler plug and the 4 screws that hold the top plate on. Try and save the gasket.

3) Mark the position of the centre actuating arm and body with centre punch marks and the arm and body. However I find it better to measure the position of the piston to get it central and then refit the arm in a horizontal position. The arms go opposite ways.

4) Using a 10 tonne (or bigger) press, press the arm out.

5) Remove the centre actuating lever by lifting it with a screwdriver.

6) Wash everything in petrol and blow off with an air line. Blow through the valve holes in the piston as well as the inside of the body and it's oilways. Remove the old rubber seal around the centre spindle.

7) To refit push the piston into the body and measure to get it central.

8) Drop the actuating lever into the body and engage in the springs in the piston.

9) Ensure the centre punch marks line up. However centrality is more important,

10) Fit 2 double lip seals into the body.

11) Press the arm back into the body. With the piston central the arm should be horizontal.

12) Refit the end caps.

13) Refit the orange washers into the opposite end, if they are damaged (through drilling), use new fibre washers of the correct size.

14) Put a smear of glue around the edge of the new core plugs and drive it in. The glue is to seal it. We used to use "red lead" but I doubt you'll get it now.

15) Fill the body with oil as you move the arm up and down to dispel air (also called "bleeding").

16) Refit the top cover, top up the oil to the bottom of the filler hole and refit the filler plug.

TO REPLACE THE RUBBER BUSHES IN THE ARM

1) Pull out the bent end of the arm

2) Drive a thin bladed screwdriver around the edges of the existing rubber seal and the arm. When the seal is broken prise the rubber out. Most will have rubber hose for a bush.

3) Press out the end with a pin. A vice can be used using a deep socket over the pin and a normal socket at the other end. I found it easier to use the press.

4) Soak the new bush in washing up liquid (mixed with a little water) and use a socket to press the bush against the arm with a piece of threaded rod with washers. Start at the end the rod will be inserted. With it being pressed gently against the arm, squeeze the bush all around with a pair of water pump pliers, the bush will enter the arm. Slowly tighten the nuts on the rod and the bush will slowly go into the arm. If it "cockles" releaser the tension, straighten the bush using a thick phillips screwdriver, refit the threaded rod and gently and slowly tighten again.

5) Hold the bent arm in a drill press vice. Using a socket on the arm use the press to push the arm onto the rod. The bush will slide further into the arm as the rod pushes through.

6) Use the same method for the end with the pins and use the press drill vice to hold the pin.

.jpeg)

Pressing the new bush in.

.jpeg)

The body with some long wheel nuts to make supports for the press. This one is partly out. It will go with a bang at around 4 ton.

.jpeg)

Pressing new bush in prior to refiiting the arm. You can do this after the arm is pressed in but I found it easier to do it before as it's lighter.

I'll post some more pictures on Friday to show how I did it. It does take time, at leasst it did me as I have a bad back and have to work slowly. I think, under normal circumstances I could do one an hour.

Tomorrow we're popping over to Le Mans to pick up tickets for the 24 hour.

4th June 2015

Went to Le Mans to collect the tickets for the 24 hour. Had a fantastic lunch in Arnage, sea food salad as a starter then a wonderful Dover Sole cooked to perfection. The weather was also perfect, 32.5 on my car gauge. We sat for and hour or so outside a cafe having a beer and a coke. How relaxing.

Wiring loom turned up. Roger's shims should be here tomorrow. Got to finish the shock absorbers in the morning with Lynne taking the pictures.

5th June 2015

My everloving wife complained all through the photo session. She took 190 pictures so I'm having a day off tomorrow to sort out the pictures.

6th June 2015

Been shopping, our guests have left and we've been through the pictures. I've posted the pictures and methods on THIS page. This way I can direct people to the page with these instructions without having to go through the main site.

7thJune 2015

Spent a few hours in the morning fitting the front and rear hub bearing. Sorry forgot to take pictures, I'll do some on Tuesday.

8th June 2015

Spent the morning polishing the Caterham with the electric polisher. This is after the respray in clear laquer. Waste of time so as the shims from Roger arrived at lunchtime I finished the diff and refitted it to the axle case. I've got to take the 7 to the CT centre in the morning for it's test (CT is the French MOT). Should be back for 0930. I'll then take a few pictures for the past 3 days.

9th June 2015

At 0800 was at the CT centre with the Caterham for its bi-annual test. Passed even though there is no handbrake fitted, Wonderful what a 20€ tip can do. Then to the chemist to get Lynne's prescription and then to the AXA insurance office to see if they will insure the 7.She wants to see the letter from the previous insurer. This says they can no longer insure on UK plates. I'll take it all with me tomorrow with Lynne to help translate. Got back, changed and started on the car. Sandblasted the rear brake backplates in the cabinet. Needed a bit more than that. I made up two studs to replace the two that were bent on the axle (centre spring hanger) there are 4 long bolts and nuts on each side plus two studs in the centre. I then sand blasted the back plates until I ran out of sand so after lunch went to Chateaubriant to get 4 more bags, Took the Land Rover hoping the steering would free off some more but it doesn't seem to be getting easier. Pictures later as I've left the camera in the garage and just too tired to walk over and get it.

OK, pictures updated.

.jpeg)

One of the rear hubs with its sealed bearing in place.

.jpeg)

Both hubs with the lock rings and nuts. By the way, if you're wondering what they're resting on, it's the weights on the front of the tractor.

.jpeg)

Two clean, sandblasted, rear backplates.

.jpeg)

A backplate bolted to the axle casing. For the second trime. I bolted them on last night but forgot to apply jointing compound (aka goo) the the mating surfaces. So first thing the following morning I took it off (after turning the axle around to make it easier and keep clean- me, not the casing) goo'd it and refitted. (you may have noticed the date of the photo)

.jpeg)

The axle casing with both backplates bolted on. I can't go any further until I get the paint, next week with some luck.

.jpeg)

The axle having been turned around is now facing the right way. I'm collecting a 5 litre can of EP140 this afternoon.

10th June 2015

It's our day out today, so I start by doing as described in yesterdays entry and then I'll start phoning suppliers who's stuff hasn't arrived. This is getting to be a major job, just trying to get answers from people. One supplier has been emailed twice for availability and price (interior trim) and hasn't responded to either email. I've bought eleswhere.

Started by pressing the half shaft out of the wrong hub. Took 8 ton to get it out. Went with a huge crack and the shaft hit the floor and bounced. I then fitted the wrong end in the new hub so had to take it off and fit to the other end. Went to 7 ton to get it in, really tight. Then started on the brake shoes. Spent two hours sandblasting them. Lynne helped and we got the old ones drilled out and new linings on with the new rivets. Photos below so I won't waste time describing it. After finishing the shoes I started on the brake drums. They're a nightmare, so I've left them in a bucket of rust remover. Looks like I'll just have to clean them as best as I can then paint them.

Then I noticed the rear backplates, which have been bolted on seem to be on the wrong sides. The handbrake slots are facing backwards. I'll swap them over tomorrow.

Drilling out a rivet.

.jpeg)

The old shoe having been removed by drilling and punching out the old rivet the new shoe has a new rivet inserted.

.jpeg)

The rivet awaiting to be hammered flat.

.jpeg)

A punch is held in the vice and located on the rivet. Then, whilst Lynne holds the shoe I whack the punch on top of the rivet.

.jpeg)

And we end up with this. A rivet hammered down tight.

.jpeg)

All done, only 7 to go.

.jpeg)

The old shoes. Apart from one, which was worn down to the rivets (but noit enough to damage the drum) they were all OK. They were 1960s technology, the new shoes are 21st century.

.jpeg)

One rivet left over. There would have been two but I damaged one getting it alighned.

I'd like to give a huge public thank you to Lynne who was a great help in rivetting the linings to the shoes. She soon got the hang of it and then there was no stopping her. THANK YOU, DARLING

So, all in all a good days work. But S L O W

12th June 2015

I've just finished yesterday’s posting so now some breakfast and start on today's chores. It rained hard in the night and the power tripped off (it does when it gets damp). I've reset it now. Funny thing was my watch stopped at 2100 last night and the clock in the bathroom has also stopped - at one minute past midnight.

First job is to swap the rear backplates over. Can't do any sandblasting as it's still raining so may strip the dynamo and starter. I'll also sort the hubs out so I get them on the right sides. Useful!

The power went off again after I'd been in the workshop for an hour. This time it wouldn't stay on. I came in a rang them on my mobile. No, they couldn't help I had to ring the "Depanage", the emergency number. I did and they couldn't help because I'd not had a croissant for breakfast, or something. After several phone calls I found a sweet young girl who not only spoke a bit of English but also called an engineer. I went outside and managed to get it to stay on. We had lunch whilst it was still on. After lunch I went back to work. I sorted all the hubs and brakes and bits into each corner with the correct spinners as a guide. I'd already swapped the backplates before the power went off. I then dismantled the dynamo and cleaned and rebuilt it. The tacho drive gearbox (on the back of the dynamo) was seized so I left it soaking in petrol and when the dried grease had been washed away by the petrol I removed the grease nipple and filled it with oil. It's much better now. I had to wrap some insulating tape around the main feed wire inside the dynamo but other than that it appears fine. I cleaned the armature and the the face of the brushes and rebuilt it.

I then painted it and put it on the cupboard to dry.

At this point the EDF engineer arrived. He thought the problem was the underground cables (we're 3 phase) but he changed the isolater anyway.

Then took the starter off the engine and was cleaning it when our guests arrived. So packed up, had a shower and changed and showed them the gite. They then went off to get shopping from the Super U.

.jpeg)

The internal wire wrapped in red insulating tape It's not neat but as it was very dificult to get at I'm sure you'll forgive me.

.jpeg)

Inside a clean dynamo.

.jpeg)

The armature cleaned and polished with wet and dry soaked in petrol. Not bad for a 66 year old wiring.

.jpeg)

A better view of the armature.

.jpeg)

The two screws that hold the front plate to the back. One cleaned and the other not....

.jpeg)

The 8" grinder with wire wheel that cleans dirty screws. (No really, a dirty screw isn't what you may think)

.jpeg)

The dynamo fully painted where it should be and "au naturale" where it should be. The reduction gear for the tachometer is on the top (left on picture) I've left the pulley and fan assembly unpainted.

.jpeg)

The starer after it's first wash awaiting the full treatment. Will have to wait until Sunday or Monday as we're off to Le Mans in the morning at 0900. If it's not raining on Sunday we may go back.

.jpeg)

The front hubs laid out on the correct sides.

.jpeg)

The rear hubs laid out on the correct sides. This was easy, all I had to do was screw the spinner to the hubs and the writing on the spinner told me "right (o/s)" and "Left (n/s)". Even I can read. Sort of.

.jpeg)

Just in case you haven't fully understood how this idiot got the rear backplates wrong this is how they should fit, with the slot for the handbrake cable facing forwards. Look at the picture above, on that picture they face backwards.

13th June 2015

We, Norm Golm from the TABC list who lives in Michigan near the lake and visiting us for the week, went to Le Mans. I had tickets for Arnage or Mulsanne corner. When I booked the web site said all the tribune tickets (above the pits) were sold. But I don't think they were as they were available the week before the race. We left at 0800 and got to Arnage at 0930. Couldn't resist so we stopped at one of the cafe's and had a French version of a full English breakfast. It was good, 3 fried eggs, French bacon (round slices and not "crinkly") baked beans, not like Heinz but real beans baked in a tomato sauce and chips. We then went to the track to find the car park I had a ticket for (had to take a bank loan for this at 26€). I thought it was the big one opposite the main entrance but it wasn't. We turned round when the traffic came to a complete standstill and went back, it was behind camping Bleu were we used to stay with the Lotus 7 Club trip. We then walked back to the road and set off towards the big roundabout by Porsche curves. Tried thumbing a lift but no one would stop for a pair of old geezers rolling along the road. The "train" thingie came along and I almost stood in front of it to stop it. We got on and it took us around the corner to Porsche curves. I thought that's where we were supposed to be so we walked along. The chap at the gate said our tickets weren't for there and to walk on a bit. We walked on to the next roundabout and asked again. A nice lady in an ACO office gave us a map of the circuit and showed us where our tickets were for. We got the next bus, then had to come back as it was the wrong bus. We then got the correct bus which took us all the way into Arnage, turned left at the level crossing and went all the way round to where we should be, about 3 minutes from where we started but the road is closed as it crosses the track. We got a couple of beers and climbed the bank and sat down It was about 1400. The cars came round at 1430 on their warm up lap. Then just after 1500 they came round on the first formation lap, about 6 minutes later they all roared past on the first lap of the race. The noise is fantastic, really load and fantastic, Did I tell you the noise was fantastic? No, well it was, the noise was fantastic. I asked Norm if I fitted a copper pipe to the TC would it sound the same but he just gave me a funny look. After about an hour, just as the cars were getting stretched out, the safety car came out and the all bunched up again. We went down and got some grub, a ham sandwich for Norm and a sausage and chips for me with 2 bottles of water. After feeding our faces we made our way right to the end of the banking and stayed there for a while. At 1700 we decided we needed to go. We got the buses back to the main gate into the village. Norm wanted to get a Tee shirt for his grandson. We went in and walked and walked and walked. The stalls that used to sell cheap Tee shirts are no longer there so we had to go into the ACO shop. 60€ for a gulf sweat shirt! Norm got a 22€ Tee shirt. We then struggled back to the car park, cutting across the big car park. We went in 3 fields too many so had to walk across the fields and across 3 ditches. We found the car and both just fell in, totally exhausted.

We set off and stopped at La Fleche for some dinner at the Buffalo Grille. We got home about 2200 and just fell into bed after a welcoming glass of wine. The two old geezers were done in.

.jpeg)

I must have taken over 100 pictures and this is a good example......

.jpeg)

.... but it was better than this!

.jpeg)

At least I could use my telephoto lens to see the large screen.

.jpeg)

I did get some pictures of cars, but not many. Most were the backs of people in front of me and an empty track.

.jpeg)

Got one!

.jpeg)

and another.

.jpeg)

A group of lads in front of us got 6 beers and burgers. I asked where mine was but they just laughed. It does look nice.

I'd love to go next year but I'll get tickets for the tribune (above the pits) and just settle down for the 24 hours and then come home. Now to find some companions.

14th June 2015

Stripped and cleaned the starter. Then went to rebuild it I was having a real problem getting the four brushes out to fit over the armature. Then I remembered how to do it. You take the two brushes from the windings out and fit the other two over the armature. Then you hold the springs out with a hook made from a bit of welding rod whilst fitting the brushes in, one at a time. Easy. I had to ask what colour and what parts were painted but then found a picture in the NTG catalouge which showed it all black other than the starter switch housing and arm which was bare metal.So that's how I painted it. After lunch I stripped the rad casing off the rad and then started to get the varnish applied by John, the previous owner, 48 years ago. It is coming off but the case will need to be rechromed.

.jpeg)

All clean on the inside and painted on the outside.

.jpeg)

Both sides!

.jpeg)

The varnish being peeled back witha rasor blade.

.jpeg)

But the chrome is scrathed, not surprising as it was 18 years old when varnished and put away for 48 years.

.jpeg)

The grille will need a lot of TLC, but will be OK.

The radiator lower frame is rotten so I'll order a new one, only £90.95 for a piece of bent metal with two studs in the bottom!

15th June 2015

Started at 0900 and tested the starter with jump leads on the new battery. Perfect, so put it away with the finished bits. Then came in to phone a UK broker who advertises they can insure cars with a 12 month green card. Spent about three quarters of an hour on an 0844 number, probably cost as much as the premium will be! At the end of all this he tells me that he'll have to refer it to the underwriter, who he asked right at the beginning of the call. He's going to email me with the premium. This is for the Caterham and I expect the premium to be about £650. I was paying 120€ with a French broker until the Government stopped them insuring non-French registered cars. About time we all had pan-European insurance and registration numbers. I thought that was the point of the EU.

I then spent the rest of the time cleaning the rad casing and all the fitments. Lunch, after which I had to phone Moss in Paris. I had ordered a tin of Black spray paint so I can paint the door hinges before sending them to the chap making the ash frame. Only problem was when I finished all I got was a black screen and didn't get a confirming email so didn't know if the order had gone through. They are closed on Monday mornings (well at least they're open in the afternoon, most places close all day Monday). Asked the chap who answered if he spoke English and he said he didn't so I asked him in French if he had my order. Yes he did and they had stock. I asked him to add a tin of red, for the grille but that was out of stock.He finishes the conversation in English. They don't like to speak to you in English but once you show you can speak French they will speak English. After all this I started work again and started cleaning all the chrome that's going for re-chroming. Then I took the hinges off the doors and started cleaning them on the wire wheel. All done I sorted out the balls, springs and pins that hold the hinges together and realised that two pins had been cut off and one spring was broken another fully compressed. So came in to ring Paris for them to add a pin kit to the order. First 4 rings it was engaged. Then I was on hold for 20 minutes, three times. During the third session of being on hold I get an email from UPS informing me they will deliver my parcel from Moss tomorrow. I hung up. Amazing, when you want them to be slow they do it double quick time. The rest of the time they are infuriatingly slow. After this I went back and de-rusted more parts, got the 66 year old rubber seals out of the window frame channels and stripped and cleaned the wiper motor.

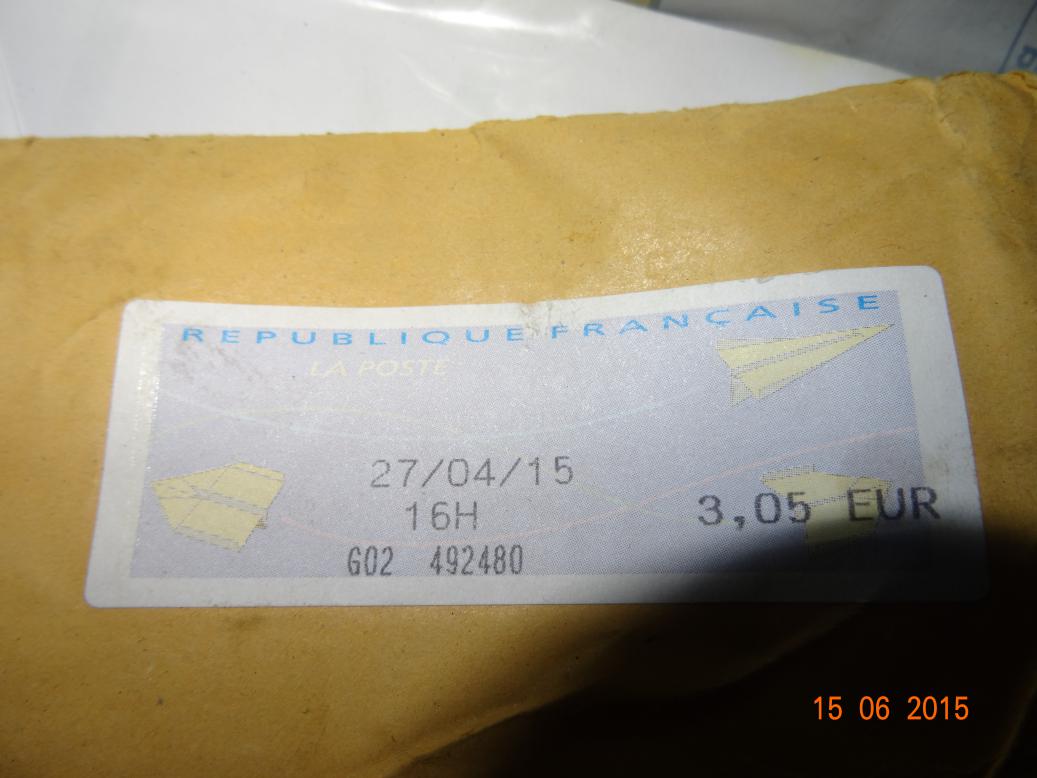

I didn't tell you about the French postal system. I posted a bunch of papers to an organisation called the FFVE who will issue a certificate for the Land Rover so I can get it on French plates. I posted this on 27th April at 1600. It came back last Thursday, the 11th, 6 weeks later as they have moved from the address I'd sent it to. See what I mean by slow!

.jpeg)

This is the lower frame of the radiator. New one ordered at £90. I'm still weeping.

.jpeg)

The windscreen frame after cleaning. It's going away, with lots of other bits to be re-chromed.

.jpeg)

Door hinges and other bits having been cleaned are soaked in Kurust overnight. I'll wash it off in the morning and paint them with zinc undercoat then the top coat which will be delivered tomorrow.

I'll take a picture of the cleaned wiper motor internals tomorrow.

Doesn't seem that I've done much today but de-rusting bits takes time.

This is the stamp on the letter which came back 6 weeks later.

16th June 2015

Another good start, in the workshop by 0900 and photographed the wiper motor. Then greased and reassembled. I had to make a grub screw for the wire as one was missing. Then wired it to the battery and switched on. woom-woom, woom-woom it went. So it works nicely. Put away with the other completed items. Last night I had coated the hinges and two brackets in Kurust. Never again, I had to sandblast it all over again to get it off. This was in the blast cabinet, so fine glass bead, and getting finer each time I use it! When the Kurust was off I tied the hinges to a string and hung them on the Siegried line. Then gave them a coat of etch primer.

Set up the sandblaster outside and started on the grill. Took ages but got 99% of the red paint and rust off. Then attacked the rad casing. The inside was black, I think it was matt black paint. It's now down the the nickel copper. And the outside is clean ready for chroming (after the acid bath they will give it).

During the day the gloss black paint from Moss Paris arrived so last thing tonight I gave the hinges a coat. I'll do more on Thursday, we're out tomorrow.

.jpeg)

The gear side of the wiper motor, the lights were just warming up hence the green tinge.

.jpeg)

The motor side. I'll take more pictures when it's painted in crackle black.

.jpeg)

Hinges on the Seigfried Line.

.jpeg)

Radiator casing, all nice and clean. It was black on the inside.

.jpeg)

The inside, no longer black, well bits are but most isn't.

.jpeg)

The grille, cleaned and painted with etch primer and drying in the sun. All I need now is the red paint.

.jpeg)

.jpeg) See the difference?

See the difference?

17th June 2015

We finally decided, last night, that the Ikea Fridge freezer was broken. It's been playing up for weeks and I told the little women to check the doors were closing. We have it in a wood cabinet and when I looked I found that the fridge had moved back and whilst the outer doors were closed the fridge and freezer doors weren't. So, our trip to Rennes food market was suspended until I remembered that there is an Ikea in Rennes. We can go to the food market, have lunch and then Ikea and home. That was agreed last night but this morning it changed. We'll go to Chateaubriant and look in But (large furniture and white goods chain) and the two big supermarkets if they have a suitable fridge freezer. I said it was a waste of time, go to Ikea and get the correct fridge at 869€ (£700 in the UK). We go into But and find a fridge with the correct size doors, freezer door 70 cms high and fridge door less than 178 cm. 54 cms wide and no more than 60 cms deep. The one they had was those measurements. It was A instead of A++ consumption but was 600€ cheaper. I liked the last bit but had reservations about it fitting into our cabinet. Paid for it and loaded it in the back of the Jazz and we returned to Pouance for lunch at the hotel. Nice seafood buffet and a fish dish to follow with fresh fruit salad for a dessert.

We get home, get the old fridge out, the new one in and out of its box. I have to turn the doors around. The screws were in so tight and even with a socket on them they were rounding the edges. I got 5 out of 6 out, the hinge plate had to go over the sixth. All done but I thought the freezer door was a bit high..... It was, it was higher than the one in the shop which was 70 cms. So we now have a fridge/freezer that is not connected to the outer doors and we have to open both doors to get the freezer door open.

Life isn't easy but I saved 600€.

On the minus side, the internet is down. Electricity last week, phone line this. Great living in rural France.

18th June 2015

Started early and .... and.... now what did I do? Ah, I know, I tidied up a bit and started laying all the completed parts out on a clean blanket. Then got the sand blaster going and sandblasted the body irons and door stay ready to go to the chap building the new tub. I'm just waiting for a hinge fitting kit to assemble the hinges to send it all to him. It's coming from Moss in London and should be here tomorrow. I then gave the hinges another spray in black paint. Cleaned the inlet manifold and tried to get the old wiring out of the wing stays. Rusted in. So I left them soaking in a rust remover solution and started on the two front brake drums. Came up not too bad. After lunch it started raining and I was running around like a demented thing getting the sand stuff away into the dry. So spent the afternoon de-rusting bits on the wire wheel. How exciting.

.jpeg)

Hinges painted black. I'll rub them down and give them another coat or two.

.jpeg)

The completed bits on a nice new blanket. At some point it should all be on this one and the other will be empty.

.jpeg)

Box of chrome bits all cleaned and ready to go. I'm going to cover the surfaces that should not be chromed in masking tape and write instructions on a label tied to each part before taking it to the factory to be re-chromed, the windscreen frame and handbrake are by the side of the box. At some time someone has welded the two end pieces to the cross bar of the handbrake so, without un-welding it, I can't get the handbrake off the shaft. I'll take a picture in the morning.

.jpeg)

Wing stays and exhaust manifold in de-rusting solution. I'm going to see how much new wing stays are and if not too expensive get new ones. If I think they're expensive I'll do these up.

Note: Just looked at the price £58 each. I'll clean these.

.jpeg)

The two body irons and door bracket all cleaned awaiting paint and shipping to the UK along with the hinges.

.jpeg)

Some of the parts I've cleaned on the wire wheel this afternoon. One bolt was ripped from my fingers and went flying across the floor. I can't find it so the blood hound (aka Lynne) will look in the morning. The same happened earlier and I spent ten minutes looking for it, stood up and it was under my feet! Idiot!

.jpeg)

And some brackets cleaned up.

.jpeg)

The remaining bits to be cleaned. This is from the box marked "body to bulkhead". Long way to go then.

A friend of mine on Facebook, Alain, published a photo of an old amplifier, a Sony from 1971. I still have my Rotel bought in 1979. It's a great bit of kit and needs two to lift it.

And the new kit (only 23 years old now)

.jpeg)

.jpeg)

.jpeg)

Proper turntable and speakers. And a good amp. Arcam. Can only play it when Lynne's out as she shouts it's too load, but I can't hear her.... because it's too loud.

19th June 2015

Carried on where I left off last night, polishing my nuts. I do love shiny nuts. And bolts, screws and brackets. All day de-rusting fittings. How lovely.

.jpeg)

The handbrake assemnly. The two rings at the end of the cross shaft are held in by grub screws so they can be reomoved and the handle slid off the shaft.....

.jpeg)

.... but someone has welded them on.

.jpeg)

The inlet manifold, It isn't green that's the lighting. It will be painted maroon, same as the engine.

.jpeg)

The de-rusted and cleaned brake and clutch pedal. It's lovely holding these when compared with the pressed out metal pedals in modern cars. That's what a man really likes, cast iron pedals!

19th June 2015 POSTSCRIPT. In France the summer solstice (21st June) is celebrated with music festivals in all the towns and villages. It's normally on the Friday night before the 21st. Tonight our village had the usual brass band and drinks at the bar. We went to Chateaubriant. Called in at Brico Marche and bought a pair of industrial gloves for painting the chassis with POR-15 and 2 lengths of rope so I can lift the chassis up high to paint underneath. Then we had a meal at Buffalo Grille, an Amarican style restaurant (Wild West style) but French. Then into the centre of town where there are a dozen bands playing all over the centre around the fantastic church they have. We parked up (found a place in the square which was actually the pedestrian part but it was a space). We walked into the centre and playing in front of the church was a Pink Floyd tribute band and they were very good, it was difficult to tell the difference. When they finished we walked down the shopping centre and sat down at a bar , ordered a beer and a Panache (shandy). Then I had a coffee after which we walked to the Irish bar for a Guinness and a coffee. Got home at 2330. Great night out in a very packed town centre with lots of people enjoying the music.

The Pink Floyd band are HERE

20th June 2015

Spent all day sand blasting and sitting at the wire wheel de-rusting and cleaning bits. The wing stays are sorted, took a while to get the rusted in cable out but did it in the end. At 1700 I stopped, tired, dirty, covered in sand, back aching and... you get the idea. I then put a new rope bought yesterday around the chassis, set up the crane and lifted the chassis so I can paint underneath. Out at the races tomorow so will finish de-rusting on Monday and (hopefully) pick up the paint Tuesday morning.

.jpeg)

Thought you'd like to see our Coypu and one of the two ducks we have. The Coypu are normally very shy creatures and if anyone is around they scurry back to their hole in the bank of the pond. However, they're used to us and just look up and carry on grazing.

.jpeg)

Painted hinges with new balls, screws, locktabs and nuts. They are going of the the chap making the tub and I'll paint them again when they get back.

.jpeg)

OK, I want to soak the new springs in old engine oil. I do not have a container large enough. So my ever-loving says to put them in a bin liner, pour the oil in and seal the end with parcel tape. Great idea. Did this using two heavy duty large liners. Poured the oil in and sealed the end. The oil is leaking out all over my workshop floor from a few holes in the liners. I'll get some garden ones next week and try again, after I've cleaned all the oil up.

.jpeg)

Cleaned brake and chassis bits in a box.

.jpeg)

Some of the larger parts laid out for a photo-shoot.

.jpeg)

The wing stays, not perfect but will be OK with two or three coats of paint. Also engine and dynamo mounting.

.jpeg)

The exhaust manifold. It's going to be painted in an ali coloured VHT paint. (Very High Temperature)

.jpeg)

Chassis in the air. I'll put another rope on the front to lift it level and I can paint the underneath. At the moment it's had one coat but by feel not sight.

21st June 2015

We had a great day at the races. It was overcast and a bit chilly when we got there but after a very nice lunch the sun came out and it was hot. I never gamble on betting but had worked out a method of working out which horse had the best record over its previous 3 races. There are no odds published in France, only tote betting is allowed. So I put two Euros (the minimum) on each of my calculated favourites. 7 races so 14€. Won one race at 3.60€. I'll stick to not betting in future.

.jpeg)

Lynne concentrating on which name she fancies. She only won on one race but more than mine, a whole 4.80€

.jpeg)

All villages in France have really nice churches. This is Sennones, just behind the track.

.jpeg)

The race.

22nd June 2015

Late start due to making a phone call to a friend who is a technology teacher and teaches 6th formers car mechanics. He has built a streamlined body on a Westfield 7 and it's very good. I asked him if he knew where I could get the chroming done and if he knew any bodyshops that could paint in cellulose and repair with lead rather than filler. He's asking around and will come back to me.

Started about 1000 and got the sandblaster up and running. Spent the rest of the day sandblasting and on the wire wheel. Nearly finished the lot and nearly run out of sand. I will get more sand tomorrow morning and then go and collect the long awaited paint. I'm also going to ask Julien if he knows where to get the chrome and paint done as he deals with bodyshops who renovate old cars. He's Frosts French agent.

I thought I took pictures of the throttle linkage, air cleaner bracket, coil and fuel pump hanging on the line having been cleaned and painted, but I didn't so they'll have to wait until tomorrow.

.jpeg)

Clean parts on te "new" blanket. As opposed to the "uncleaned" blanket.

.jpeg)

The other end of the "clean" blanket.

.jpeg)

The "unclean" blanket. The carbs can go over to the "clean" blanket, they're done. So only a few boxes to do now.

.jpeg)

The chassis ready to lift. It's balanced and lifts evenly. Hopeing to get the painting finished tomorrow as we're out all day Wednesday and it will give it time to dry properly. Then Thursday start rebuilding. At last.

I got the Caterham insured with a UK underwriter with a 12 month green card. Only £600. (ONLY!) was paying 120€ for it in France. I also phoned Julien the agent for Frosts and all my stuff is in. So early start to Chateaubriant for more sand then to Avrille (near Angers) to collect the stuff from Julien. Hope to be back for 1100 and start painting. Spoke to Peter Edney about all my outstanding parts and he assures me they're on the way. He was out last week at MGLive. So, all-in-all a good day.

23th June 2015

Up at 0645, breakfast and out by 0725 to Chateaubriant to get 4 more bags of sand. Then all the way back and on to Avrille, which is near Angers to get the paint, 2 US quarts and an aerosol, brushes for cleaning oilways in the engine, fuel tank cleaning and sealing kit, 2 tins of paint stripper, a gallon of rust remover and an aerosol of VHT silver. 400€ later I was on my way back. Got back at 1045, changed and started work. I've painted the chassis both axles, wing stays, shock absorbers and lots of brackets etc. We're out tomorrow and I'll give the stuff I've painted today a final coat of the correct colour black on Thursday morning and cut grass in the afternoon. Shoud be able to start rebuilding on Friday.

.jpeg)

The air cleaner bracket.

.jpeg)

The throttle pedal

.jpeg)

Fuel pump. I shouldn't have painted the lower part so, tonight, I sand blasted the paint off.

.jpeg)

The coil.

.jpeg)

The wing stays, I know the picture should be rotated 90 degrees but they're still wing stays! Also they are not silver that's a reflection of the flash.

.jpeg)

The exhaust manifold after 2 coats of VHT flat silver. I think it looks right.

.jpeg)

Shocking. The shockabsorbers hanging on astring having been painted. I expect the string to break with that weight but it's been OK so far.

24th June 2015

Our day off and we planned to go to Rennes food market. As usual with the French, there's a huge article about the market, second largest in France with all the information you may need, except which day it is. We've been before and the farmers market is on Saturday and we went with some people who were staying here and we were pretty sure it wouldn't have been on a Saturday.

First thing this morning I noticed I couldn't send any emails. I checked it through and found a notice that I was using a trail copy and the trial had expired. I bought MS Office about 3 months ago and had noticed that Word had said "trial system". So I downloaded again and entered the key and all was well. I hadn't noticed that Outlook still said "trial system". I found the email with the licence key and then noticed it said the £80 system I'd bought did not include Outlook and a few other things that didn't bother me. So I emailed the company I'd purchased if from asking if they could provide an Outlook key and how much. A 2 line answer came back saying they don't have any Outlook only licences. Nice customer support. Go onto Amazon and spend another £80 on an Outlook 2015 licence. Go to download and install and it comes up with "Gateway error", try again. Same happens on second attempt. I then look and see that it has downloaded some files so I click on one and it starts configuring. Takes about 10 minutes to get to 99% and then says it can't finish as another copy of Outlook is running and I need to close it. I do so and then find I have to start from the beginning. By this time I'm incandescent with rage. It then works. I then clean up the registry and reboot. It starts up the old copy of Outlook and to get the new one I have to re-install. This all started at 0830 and it's now 1130. We set off to Rennes and try and get in the park and ride car park but it's full. So we drive into town and try and find somewhere to park near the station. As far as I remember the market is down a street opposite the front of the train station. We drive around, get into a bus only street by mistake and I'm getting hotter and hotter in both senses. Eventually we find a car park where all the hire car companies park, by the side of the station. Take a ticket and park up. There’s a long walk to the station. In the end I was so tired we had lunch at one of the many restaurants opposite the station. It was great, oysters and seafood salad for me and a Chevre salad for Lynne. We sat in the sun for about 2 hours and then asked where the market was. It's about a 20 minute walk from there and the food market is on a Saturday. So we had a walk around the shops and came home. We now know where the market is (St Anne’s metro station) so will go on the next free Saturday.

25th June 2015

Was going to get an early start but having been awake since 0400 I fell back to sleep and didn't wake until 0800. Got the chassis in the air and started painting with the Moss correct colour black. Expected it to be the same as the POR-15 but it's not. It's very shiny. Looks good. Finished painting by lunchtime and then fell asleep after lunch so started cutting the grass at 1500. I was going round the large field as I do and then I go through the orchard and round again. Problem is that coming from very bright sunlight (it was 28 in the shade today and the sun was blazing down) into the shadow of the tress I can't see anything, may as well have my eyes closed. See the result below. It then got worse.

.jpeg)

The difference betwen the, dull POR-15 and the, shiny Eastwood chassis black from Moss.

.jpeg)

The chassis suspended for painting.

.jpeg)

And back down again, ready to be rebuilt.

.jpeg)

Lynne was telling me that she wanted a Poncho when we were in Sheffield but for some reason Tanya, our daughter, wouldn't let her buy one. So I bought one and it arrived today. You can see how happy she is.

.jpeg)

See what I mean. Doesn't take much.

Now then, the tractor. When I drove into the darkness of the orchard I was too close to one of the big apple trees and hit the roof against a very big branch. Nearly tore the cab off. I carried on but noticed the windscreen had been moved sideways so one edge was out of the rubber and the other edge was past the frame. Not much I could do. When I stopped for a drink I saw the full extent of the damage, the roof had been opened like a sardine tin. No wonder apples were hitting me on the head! I tried to move the screen back into position but it was tight so I left it. An hour later and I hit a bump and the top side rail of the cab came away from the rear section. The screen fell out and my rear wheel ran it over and smashed it. The front of the cab is now dancing about like a wild thing. I finished cutting and parked up. When I have an hour I'll take the whole front section of the cab off. Should be cooler in there on very hot days.

At some point I asked Lynne to go to the next farm and get some diesel. She got 100 litres of red and was amazed it only cost 60€. I explained. When I was filling I asked her to jump in, switrch the ignition on and check the fuel gauge. Later, when I was driving round cutting grass, there was a huge plume of smoke from behind the dash and the ignition light came on. The plastic toggle switch will no longer move so I'm guessing it burnt out and has welded itself together. I blame Lynne, every electrical appliance she touches breaks. When we were first married she had 8 new irons in 7 years! Only joking, darling, it's not your fault, it was the wrong switch fitted by the previous owner. I'm surprised it's lasted this long. I think I have a heavier switch in my stock so I'll change it when I get a minute.

.jpeg)

Oops, not many tractors with sun roofs. Or no roof!

26th June 2015

Had a doctor’s appointment at 0945. I wanted to find out what was happening about my back and see if he could do anything about my left arm which has tendonitis but is getting worse. The doctor is a good friend and I'd asked him if he knew where I could get the chrome from the car re-chromed. I can't find anywhere but have now got the name and address of a company that will do it but they only do work for companies, not individuals. Anyway, Camille has found one that will do it so I plan to get it all prepared and just take it there. Just waiting for tie on luggage labels to arrive so I can tie the instructions for each piece on so there are no mistakes. Appears that the specialist dealing with my back is waiting for a proffesor to report but Camille thinks the professor has reported and it's back to the other doctor. He spent 10 minutes on the phone and has to email the doctor to tell him to get the problem solved! He has also got me rubbing in anti-inflammatory cream and a course of physio for my shoulder.

As is always the case, I didn't see the doctor until 50 minutes after my appointment time and was in there 45 minutes (this is why he's always running late!)

Got home at 1155 and I had an email from a friend of mine who is a college lecturer on motor engineering giving me the name of a bodyshop who can repair and paint the body. So I rang them and was asked to ring back at 1400.

Had lunch, and then went over to the garage to spread the cat litter I bought at the supermarket on the oily floor. I wanted to oil the new springs in old engine oil so placed the springs in two heavy duty bin liners, poured the oil in and tied the end in a knot. The liners leaked and there was oil running over the floor. So spent 15 minutes clearing this up and then went back in to phone the garage. I think it'll be OK; I have emailed them and await an answer.

Now for the rebuild to start. Wiped the oil of the rear springs and went to fit them.

Not sure what the law's called, maybe sods law, but having spent 3 weeks sandblasting and painting all the parts, the first parts I go to fit are not painted! I've put all the spring hangers under the chassis at each corner they go and missed painting them. Idiot!!!!

So I painted all the spring hangers and got the front pins on the front springs on. That was it. In the morning I've got to strim around the gites and go shopping for our guests arriving in the afternoon. I will carry on for a few hours after I've done my chores.

.jpeg)

Cat litter on the oil spillage. It will suck the oil up and I'll sweep it up tomorrow. This is the second 10 liter bag I'd used.

.jpeg)

The rear spring in position awaiting hangers to refit it.

.jpeg)

Rear axle in position awaiting spring to bolt it to.

.jpeg)

Spring hangers hanging on the line drying......

.jpeg)

.... and some more.

.jpeg)

And the only constuctive building done today, the front pin of the front spring in, tightened and lock tabbed. Both sides are done.

27th June 2015

I went to a bodyshop recommended by Jean-Marie, our friends from the Tours region who has built a fully enclosed body on a Westfield. They can do the repairs and paint it. They specialise in renovating Citroen DS and 2 CV's and know how to do old cars. One problem solved. I then came home and went shopping for the folk arriving in the gite this afternoon. They wanted a couple of bottles of Champagne and whilst looking I saw the local fizz from Samuar for only 6€. So I bought one for us. Got back, put the wine in the freezer for 15 minutes and had lunch. Lynne drank half a glass and then went for a nap. She's suffereing, poor girl, with the heat. It was in the mid 30s. I finished the rest of the bottle and her half glass. Fell asleep at the table, then staggered into the lounge and fell asleep on the settee waking up ay 1700. So, no work done today. I'll get cracking tomorrow as I want to order whatever is missing to reassemble the suspension.

28th June 2015

Started at 0930 by getting the front spring shackles on. Then changed the bolts that hold the axle to the spring. Our guests then came over and asked how they put the hot water on. It should be on says I. After half an hour testing I determined the boiler installed last June isn't working. Lynne phoned Angela and the little darling came straight round and cleaned the other gite, moved the bedding across and, when our guests came back they moved into the MG suite with hot water. When they arrived yesterday the gas had run out so I had to change the gas bottle. Luckily I keep a spare. Not a good start to their holiday, let's hope it goes well from now on. At least the weather's good, if anything it's too hot! Lynne is going to Brico in the morning to see if they will deal with the boiler under warranty. I've asked her to speak to Arnold, who knows me well, and see if she can buy a new element so that I don't have to take the whole boiler out. I'll change the element, return the broken one and when they're happy it is broken get a credit.

Anyway, It was hard work getting the axles back on, mainly finding all the corect nuts etc. It doesn't help that it's in the mid 30s and just moving is sweltering work.

When I went shopping yesterday Lynne aske me to get some larger pots for her house plants. Now, let me tell you a secret. Lynne is a mass murderer of house plants. In the past every one we've had has died. But those we now have are thriving. She planted two tiny cactus four years ago. they are now so big she had to put them in larger pots.

.jpeg)

The O/S front sping and axle located.

.jpeg)

The N/S You can see the unpainted new shackle pin bolts.

.jpeg)

Rear spring on but not fully tightened. I'll tighten and split pin the nuts in the morning and do the other side. Then to fit the axle to the spring.

.jpeg)

Lynne's cactus. These were the size of my thumb 4 years ago.

.jpeg)

Two plants that needed re-poting. The one nearest the camera was bought by some guests who she did some washing for. Maybe i should say she put their clothes in our washing machine. They bought her this plant as a thank you.

.jpeg)

This one has doubled in size in the last 4 years. Note the white flower, top right.

.jpeg)

And she is now getting adventurous, a cutting she's taken and planted. Wonder if it'll thrive. Looks like it may. I keep asking her to plant a vegatable garden outside, after all we have 10 acres of fields and buy all our fruit and veg in the supermarket.

29th June 2015

Down at 0700 and getting ready for an early start when Lynne followed me down and put paid to all that. I'd asked her if she could go to Brico Marche for me to check that the boiler that's packed up and was bought 04/06/14 was under guarantee and if so could we buy a new element, return the old one and if found faulty credit the new one. She thought it would be a good idea for us to go together to Brico then lunch and shopping at Leclerc. She can't really cope with the heat. So I agreed but said I wanted an hour or two in the workshop. Get the springs mounted the correct way up and pack up. We get to the Brico at Segre and Arnold, the manager, points out that it was bought at Brico in Chateaubriant. So off we go to Chateaubriant where the Brico Marche is next to the InterMarche super market which has a restaurant. So we had a nice lunch, did the shopping and then went into Brico Marche. The element has a one year warranty but the manager suggested pressing the reset button on the thermostat. I didn't know there was one so I'll try that first thing in the morning. Hope it is that, mainly because I don't want to spend time draining it down to change the element.

Now, nobody noticed that the picture of the rear spring, taken yesterday shows I've mounted the rear shackle upside down. I thought something was odd and the axle was a long way from the spring. At 0300 this morning I woke with a start and realised what I'd done. So I got cracking at 0800 and before 0900 hade got it correctly mounted. Then spent 15 minutes looking for the rear shackle pin for the other side and, even though I thought I had a new one, I couldn’t find it. I was coming in to order a new one when I literally tripped over the old spring and saw the old pin in the spring. Took a minute to get it out, another few minutes to clean it up and by 0950 both springs are on. I can't find the nut for front shackle so will order one now. I will also get some new grease nipples.

I had sent an email to Gliptone for a leather restoration kit and dye to colour the seats. I sent them a swatch to match the dye. Today I get an email back asking how much dye I want even though I had said it was for an MG TC which had 2 squabs and a one piece backrest. So I arranged the seats (which are in my room having saddle soap applied) and took a picture to send them.

.jpeg)

This is upside down....

.jpeg)

.... and this is the right way round. Keep telling you I'm an idiot.

.jpeg)

Getting there. I'll bolt the axle to the springs in the morning and them drop the front on to the creeper and lift the rear on the crane to move it back so I can sweep under it. I'm fed up working in dust and muck. Then I can put it back and refit the brakes and hubs to get it on wheels. I've also got to start de-rusting and rubbing down the body panels so I can deliver them to the bodyshop.

.jpeg)

The seats. Will be interesting to see how they look after the cleaning and dye.

30th June 2015

Started at 0800. Took me 5 hours to get the 4 bolts that hold the axle to the spring in one side. I can't bend very easily so didn't notice the shackle was slightly off centre. I went out and bought a G clamp 80-200 mm but it didn't close the spring to the axle, then I wedged the chassis to the roof joist with a step ladder and jacked up the spring. The holes wouldn't line up. In the end I used two long bolts at diagonal positions, knocked the lower plate square and having closed the gap, got the other two normal length bolts in the swapped the long ones for normal length. The other side took 3/4 hour. Having got the rear axle bolted in I laid the front axle on the floor creeper, lifted the rear of the chassis with the engine crane and moved the chassis right back. A really good sweep up, push the chassis back, use the crane to take the centre tub outside and finish cleaning the floor. Cleaned and put all the tools away, laid the parts for the hubs by each corner and packed up for the day. The temperature reached 37c this afternoon and I probably sweated a kilo of water.

After lunch Lynne and In went into the gite and looked under the boiler. Little hole with a red spot showing. Stuck the point of a pen in the hole, the red spot dissapears. Half an hour later we have hot water. Magic.

.jpeg)

The 4 bolts that gave me grief. Notice one new bolt is longer than the others. I wonder if that's by design. It's still not long enough to pull the spring up to the axle. It may have helped if the bottom bump stops had been removed.

.jpeg)

The top of the O/S. The paint will need touching up.

.jpeg)

Rear axle on. A couple of days when I'm back (and it's cooler) should see the brakes and hubs on and the chassis rolling. Then I must get the paint and rust of all the panels ready for painting.

I WON'T BE WORKING OR POSTING TOMORROW (OR MAYBE THURSDAY AS WELL). IN THE MORNING I HAVE PHYSIO FOR MY SHOULDER (TENDERNITIS) AND THEN OFF TO HOSPITAL FOR TESTS FOR MY BACK. THEY MAY KEEP ME IN TOMORROW NIGHT AND MAYBE ON THURSDAY AS WELL.

Ok, move along to July now.....

March April May June July August September October November December January February March April May June Tech. Index Gallery