HOME WELCOME SEVEN ELAN ELISE MIDGET FAMILY GUEST BOOK

Carbon upgrade Engine upgrade Other upgrades Rear brakes 2004-2006 upgrades Accident rebuild pages Refurb 2014-15

Introduction February 2007 March 2007 April 2007 May 2007

![]()

Sunday 1st April: April fool and nowhere near ready for a blat! Lynne and I spend most of the day finishing the cutting of the dash and fitting it back in the chassis. We (I) have a short on the side lights. I can trace that there is a side light wire going to earth but it's difficult to see which of the 8 it is. In the end I trace it to my stupidity (caused by poor eyesight) when I temporarily earthed the fuel gauge tag! Well a tag looks like it should go to earth and the wire looked black (it's dark green/black). During this episode I bridged the fuse and burnt a wire to the oil pressure gauge out. Lynne panics when there's lots of smoke coming from behind the dash. I fall about laughing, as I make a new piece of wire.

Working away looking for a short. It's behind you! (was the fuel gauge wire

in the boot area being run to earth)

Working away looking for a short. It's behind you! (was the fuel gauge wire

in the boot area being run to earth)

The result of a day and a half's work

The result of a day and a half's work

Monday 2nd April: As I'm up early I take the opportunity to put all

the tools away and sweep up. That takes nearly 2 hours! Whilst waiting for

my little helper I rivet the vertical panel to the scuttle (scuttle is new,

panel is existing). I then rivet the horizontal panel to the chassis. Problem! I

fitted the top oil tank mounting bracket to the chassis and now I need to drill

the rivets out to fit the panel first. First mistake that needs rivets drilling

out. The scuttle is then fitted in place. measured for the fixing studs and

holes and slots are cut.

Scuttle in place.

Scuttle in place.

Scuttle now in place but only fitted loosely. I will need to set it when the

nose cone is in place and the bonnet can be fitted. The scuttle is then

positioned to the bonnet.

Scuttle now in place but only fitted loosely. I will need to set it when the

nose cone is in place and the bonnet can be fitted. The scuttle is then

positioned to the bonnet.

Last job is to tidy up the rear loom and enclose it it plastic

bendy tubey stuff.

The tidied rear loom. It know goes around the sides of the tank in the nice

plastic tubey pipe. Before it was gaffer taped to the tank, you can still see

the marks the tape has left. May add a few ounces but it is neater.

Tuesday 3rd April: I order the new ignition amp from Burton. I also

order a new coil as mine has a crack around the + tower. As the postage cost is

a whacking £22 I may as well get all I can for the price.

The Caterham parts arrive just before lunch. However a friend pops round to

lend me a ADSL filter to try. As he arrives at 12:45 we have lunch and two

bottles of wine. No more work done today.

But... just time in the evening to fit the rear shock absorber bolts. That is

after I run a tap down the threads to clean out the powder coating.

Wednesday 4th April: Cut the long wheel nuts down to size. They are

the tube type fitted to Revolution wheels.

Refitting the cut down wheel nuts. These wheels will be replaced with the

Superlites when the tyres arrive.

Refitting the cut down wheel nuts. These wheels will be replaced with the

Superlites when the tyres arrive.

Lots of little jobs follow. Fit the anti roll bar, the new rear brake pipe,

the battery leads for the Anderson plug, bring over 3 bags of 35kg cement.

Can you guess why I need 3 large bags of cement? basically because I'm a big

fat bastard and it's time to set ride heights so need 108 kgs in the drivers

seat to make up my weight. So I'm now 3 bags of cement.

Setting the ride heights wasn't too bad. It's a temporary job until the new

tyres arrive and the lighter wheels can be fitted. Then run two thin wires

between to poles held on axle stands across the front and rear and set the

track. Check the camber but need to make a flat steel section to fit the

magnetic camber gauge to. I'm not happy about the camber, I'll recheck it over

the weekend when my son is here.

I align the steering column and take a drivers eye view of the dash whilst

sitting in the car.

Drivers eye view. They're not seams in my jeans they're the arms of my

glasses!

Drivers eye view. They're not seams in my jeans they're the arms of my

glasses!

A complete engine except for the amplifier and coil. It was a real bugger to

get off, it's going to be even harder to refit!

A complete engine except for the amplifier and coil. It was a real bugger to

get off, it's going to be even harder to refit!

Thursday 5th April: I make good the clutch pedal stop - again!

Must be the third time I've done this and I'm still not happy. Then we have

tantrums (mine) whilst bleeding the brakes. I have brake fluid going all aver

the place because I can't find my trusty old bleed pipe which was last used in

Sheffield. Eventually get it done but not a good pedal. I'll leave it for

now and ask my son to give me a hand (more to the point a leg!). I then spend

some time adjusting the mark 69.6 throttle pedal (remember that?) and moving the

pedals about to get a good heel/toe position.

That's it! Work suspended whilst my son, Kerry, the two

Neanderthals and the new baby, my first grandson, 7 months old arrive today.

They've been in Paris for two days.

So I spend the day cutting the grass. First cut of the season so there's grass everywhere. It's about a foot high and the cutter leaves it laying where it's cut. Just as I'm half way around the small field I hit a telegraph pole which is by the drive. The impact shears 3 bolts on the cutters upper arm. I get the 4th bolt out with Lynne's help and will finish the cutting in the morning as it is.

Before trying to demolish a telegraph pole this drive belt cover fell off in

the middle of the field. I think this mower is trying to tell me it's past it's

best.

Before trying to demolish a telegraph pole this drive belt cover fell off in

the middle of the field. I think this mower is trying to tell me it's past it's

best.

The end plate which had 3 bolts sheared off. The red arm is the connected to

a hydraulic arm which lifts the cutter at right angles, the white tube is part

of the hood.

The end plate which had 3 bolts sheared off. The red arm is the connected to

a hydraulic arm which lifts the cutter at right angles, the white tube is part

of the hood.

A naked grass cutter. Works just as well

A naked grass cutter. Works just as well

Can't you tell this seven month old baby is my grandson?

Can't you tell this seven month old baby is my grandson?

Friday 6th to Monday 9th April: A weekend with Simon, Kerry, Leanne,

Robert and baby Malakai. We sat around getting to know our grandson on Friday.

On Saturday I dragged Simon to Dinan to meet Bruce from Arch who had my roll bar

and two tyres. In the afternoon we double checked the track & camber. Both

needed adjustment and I'm not happy we got it right. I need to run the car for a

few miles to "settle" the suspension and then check it all again. We

bleed the brakes again and they're OK, not brilliant but OK. I'll come back to

them when I've given the brakes time to bed in.

Sunday's plan was to visit the zoo. But we have to go to a clothing store for

the kids. I got some shorts and tops but that's a different matter, as I'm done

and paid in 10 minutes whilst we wait 45 minutes for the Neanderthals to choose

their gear. We then go to La Fleche which is about an hour away. It's the place

they used to feather arrows, hence Fletcher. We go into a Leclerc to get a ADSL

router. Choose the only one on sale that isn't tied to a contract (we have one

of those) and pay 99€. We then go to Buffalo Bills for lunch. I was dreading

it but it wasn't too bad and the Neanderthals seemed to like it - still

complained but ate it all.

By the time we get out of there and to the zoo it's 4:30. Executive decision

and we leave the zoo for tomorrow. At 100€ for 6 I want more than an hour and

a half!

Get back, bath and feed the baby and go out to a restaurant run by an Italian

girl married to a Lebanese. They are getting to know us and Lynne gets 4 kisses.

4 is reserved for family and good friends. they must really like our money!

Still they are a nice couple and the foods good. And cheap compared to UK restaurants.

All the weekend we've been singing "We're going to the zoo, zoo, zoo and

you can come too". At last we make it. get there at 12 and make a beeline

for the food. Salad and frites, not bad, but expensive for what it is. Then we

start walking around the zoo. We see the falconry, good. Then a bit more of a

walk and we're off to see the seals perform. I've heard the joke about blowing a

seal (see Wednesday). The seals are excellent and very amusing. We then walk

about some more by which time I'm struggling to stand up let alone keep up. We

leave at about 5 and I make it straight back to the car and get 20 minutes kip

before the rest arrive from the gift shop.

Back home and the girls make spag-bol and we say our goodbyes as they will be

leaving at 5 in the morning. They are booked on the 12:00 ferry from Dunquerke,

It's been marvelous meeting our grandson for the first time since he was a

few weeks old. He's a very happy, smiley, laughing character so doesn't take

after me. I'm looking forward to the time when he's old enough to stay with us

for a few weeks in the summer.

Now, back to the missing internet. The box that said it was an ADSL router

wasn't. It's a 4 port hub with a cable for a ADSL modem. The store was closed on

Monday so I've now got a 2 hour journey to take it back! Simon brought a Cisco

800 series router with him and after an hour or two of setting it up we are back

on line.

Three generations of Verona, Scary!

Three generations of Verona, Scary!

Mum, Dad and baby. They've called him Malakai which I thought was a biblical

name but apparently is Japanese.

Mum, Dad and baby. They've called him Malakai which I thought was a biblical

name but apparently is Japanese.

Neanderthals called Robert and Leanne. Mum is in the middle. (All teenagers

are Neanderthals - I was)

Neanderthals called Robert and Leanne. Mum is in the middle. (All teenagers

are Neanderthals - I was)

Granny!

Granny!

Leanne, caught unawares.

Leanne, caught unawares.

Tuesday 11th April: All morning is spent cleaning the gites and

changing bedding and towels. Also take about 500 beer and wine bottle to the

recycling bank. Someone had a good week! Lunch and then back to the car.

Spend some time doing the clutch pedal and moving the brake and clutch pedals

side to side - again. Then struggle to get the coil and amp refitted.

Time to start the engine. 3 pumps of the throttle and push the big red

starter button. Vroom it goes first time. Check I have oil to the head and warm

it up at no more than 1500 revs. Get the carbs about right and then turn my

attention to the ignition timing. My new adjusting rod is fantastic. If only the

clamp was easier to get a spanner on this would be a few minutes work. I

eventually get the clamp loose enough to move the distributor. Set it at 5

degrees at tickover. Then warm it up and with Lynnes help get it running at 5000

rpm. Lynne has to watch the rev counter whilst I turn the throttle screw. She's

terrified of the noise but does a sterling job. The gun is set to 26 degrees and

pointed at the crank pulley. You know it was a great idea to mount the oil

thermo upright behind the rad. If only I could see the crank pulley I would pat

myself on the back. Finally find a position where I can get the light on the

pulley and can see it as well. Spot on. Undo throttle screw and switch off.

Now to tighten the distributor. Arm placed under carbs from behind (why does

that sound like a sexual fantasy?) tighten clamp and then the screw that hold

the clamp itself. Remove arm to find.....

... one burnt arm! Funny how you don't feel it burning when pressed hard

against a very hot cylinder head.

... one burnt arm! Funny how you don't feel it burning when pressed hard

against a very hot cylinder head.

Our guests arrive and the blokes, two Lotus Seven Club members, are only

interested in the car. We spend about an hour looking it over whilst the girls

are shown the gites.

Time for it's first drive. I'll ignore the small pool of oil collecting under

the car. It's weeping from that bloody joint! Start up, depress clutch but can't

get it in gear. The pedal seems spongey and is set for it's normal 1"

travel. Too late now, I'll return to it in the morning.

Wednesday 11th April: Early start and jack car up to get at the hose clips on

that bloody joint. Get the jubilee clips off and some Mikalor stainless clamps

on. Tighten clamps but they are too large and are tight without clamping. The

root of the problem is metric pipe on an imperial connector. So I send Lynne

into the barn with the gites to get some metric copper pipe to make a new

connector. She comes back with a very long pipe being dragged behind her and a

very wide grin on her face. It's the right size pipe so I cut a piece off and

after some struggling get the two pipes on it. The problem with Mikalor clamps

is they do not have a wide enough open-close span. 2mm is not enough to get the

clamp on and tighten the clamp so it clamps. I get a jubilee clip on one end and

piece of copper packing on the other with a Mikalor clamp tightened but not

fully closed.

Now get Lynne to sit in and we'll bleed the clutch. She just cannot reach the

pedal so I find a large box to put behind her. She's now sitting on the edge of

the seat and can just push the pedal. I release the stop bracket and we bleed

the clutch. Box and Lynne removed I can now get it in gear. When I had the

engine out I replaced the clutch with the twin plate unit. I had had a single

plate AP paddle assembly in whilst AP made a pair of plates with hardened

centres as the normal splines kept stripping. In the process I had a good look

at the release bearing and decided it was wrong. I fitted a bearing with a

curved face in place of the flat faced one that was in. The clutch now has far

more than 1" travel and is far more progressive.

So, for the first time since my accident on 17th December I drive the car up

and down the driveway. The speedo isn't working but other than that all seems

fine. I get it back inside the workshop, get out the car and find oil pouring

out from the engine. It's on the cam belt and spraying everywhere.

Jack up and get underneath. The sump's leaking and one of the new oil filter

pipes will need attention.

I HATE MY CAR!

Time for lunch. Then decide to have an afternoon off and read Classic &

Sports Car which has just arrived. read and doze in the warm sunshine. I needed

that after the hectic weekend. Tomorrow I'll drop the sump and tighten a hose. I

also think that bloody joints still leaking. I'll fix the sump and oil filter

first then look at the joint as it may be one of the other leaks running onto

the joint.

Thursday 12th April: Early start (about 8:30) to drop the sump and fix

the leak from that bloody pipe. Sump down in about 10 minutes and find the half

round rubber seal laying in the sump rather than where it should be. Red

Hermatite will fix that, thinks the Verona. Now whilst I'm here.... There is an

oil pick up pipe which goes from the sump to the pump and has a short rubber

hose connecting it. On this hose are two hose clips. Right, I'll have them off

and fit two normal Jubilee clips and then put these two clips on that bloody

pipe. That takes all of 2 minutes and after 3 tries at getting the sump back up

whilst keeping the half round seal in place the sump is back on. All tightened

up and attention is turned to replacing the clips on the bloody hose. I have to

undo the clips to wrap around the pipe and space is tight (isn't it always!).

These clips have rusted under the worm screw and won't undo all that easily.

The first one I turn my attention to breaks. The worm screw housing comes off

the clip. bugger!

In the meantime a parcel arrives from Richard with the new carbon boot lid. A

quick look and I carry on fitting clips to that bloody hose. It's not only

difficult to get too but I've hurt my thumb and it's almost impossible to close

the clip to get it started. After a lot of swearing I get the other clip on and

tightened. It strips! I suppose you could have written that. I then tighten the

clip on the hose to the air filter. It takes a full turn before closing fully. I

add a second clip for insurance.

"Lynne! When you pop round the garage to pick up the wheels can you get

me some clips." Why didn't I just get new clips in the first place?

Lynne sets off to pick up the wheels, which have had the new tyres put on,

visit the bank and book the Pug in for it's Controle Technique (MOT to us).

While she is out another 2 boxes are delivered. The stuff from MOG at last, two

weeks late. The excuse for late delivery was the delivery company had brought

them to France and returned them to Germany. Good story. That was about 10 days

ago. Wonder why the invoice inside is dated 9th April. You can figure it out.

So, I leave the bloody pipe and fit the nose cone. Easy job, rivet the clips

on and it fits without hassle. As I finish Lynne returns. The man at the garage

says he hasn't clips to fit the hose I'd sent for a measure. I ask Lynne if

she'll help me cut the two large holes in the bonnet. She storms off in a huff.

Something about she's been half way around the world and needs a coffee. I take

that as a no then.

The new nose cone. Not sure I like the black edging on MOG's stuff but I

suppose it's a matter of taste. I'll live with it. Of more concern is the

weight. For a carbon item it's very heavy.

The new nose cone. Not sure I like the black edging on MOG's stuff but I

suppose it's a matter of taste. I'll live with it. Of more concern is the

weight. For a carbon item it's very heavy.

So I start cutting the oblong for the air filters. Trying to hold the bonnet

and cut round the line drawn on the masking tape on your own is not a good idea.

The inevitable happens and I slip, making a small graze on the edge of the

bonnet. With temper frayed I storm in to DEMAND help. She quietly tells me she's

coming out as soon as she's finished her coffee.

I jump in the Pug and drive off like a looney to get the bloody hose clips

for the bloody hose. The man in the garage shows me some very nice Jubilee type

clips with blue plastic over the worm screw. They'll do nicely thank you. I get

6, 2 for each side of the joint that leaks. So 4 for that bloody hose and 2 for

the oil filter hose.

I get back and we both enjoy a pleasant afternoon cutting holes in the

bonnet. What else do loving married couple do on a warm sunny afternoon?

Holes cut but I'm not happy about the exhaust side. When the bonnet was ali

the hole was cut very close to the bonnet. But with carbon I've had to leave a

bigger gap to avoid burning the carbon. It's OK but not as "organic"

as it was. Lynne disappears and I fit the two clips at the rear and then the two

springs to the front. I have to let the car down for this. It's still up on axle

stands as it's easier to work on when it's higher.

The air cleaner aperture in the bonnet. The apparent gap is in fact a shadow.

Note the stick that covers my little scuff mark. Cut from a LUKE seat belt label

it says "Racing"

The air cleaner aperture in the bonnet. The apparent gap is in fact a shadow.

Note the stick that covers my little scuff mark. Cut from a LUKE seat belt label

it says "Racing"

The exhaust side. I've left the masking tape on the top for the moment as I

need to cut a bit more from the top. I'll then cover the inner edges with a

2" wide strip of cool tape.

The exhaust side. I've left the masking tape on the top for the moment as I

need to cut a bit more from the top. I'll then cover the inner edges with a

2" wide strip of cool tape.

I fit the 4 hose clips to that very nice hose that used to leak.

A bit of a struggle but no real problem. Oil wiped clean and I'll inspect in the

morning. But I can already see that the nice hose is not leaking any more. New

hose clips, now why didn't.........

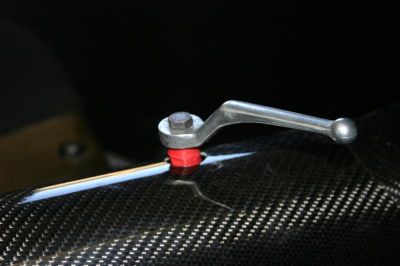

That bloody join in the oil pick up hose. The bolt is the lower wishbone

fulcrum. The new, blue hose clips are holding it nice and tight. It's a very

nice hose. now

That bloody join in the oil pick up hose. The bolt is the lower wishbone

fulcrum. The new, blue hose clips are holding it nice and tight. It's a very

nice hose. now

The hose clip saga. The top clip (on left) is a Mikalor stainless clamp. Its

19-21mm. It would do very well if it would open up enough to fit over the pipe.

The next one down is 23-25mm and fits over the pipe but closes completely

without clamping the hose. The third is the clip I swapped on the oil pick up

from the sump and the bottom clip is the new one obtained from the local garage.

I would have saved myself many hours and a lot of agro had I got new clips in

the first place.

The hose clip saga. The top clip (on left) is a Mikalor stainless clamp. Its

19-21mm. It would do very well if it would open up enough to fit over the pipe.

The next one down is 23-25mm and fits over the pipe but closes completely

without clamping the hose. The third is the clip I swapped on the oil pick up

from the sump and the bottom clip is the new one obtained from the local garage.

I would have saved myself many hours and a lot of agro had I got new clips in

the first place.

Springs fitted and the bonnet looks good. Scuttle positioned and tightened

and it's now gone 7. We're going out for a meal with our guests who have just

returned from their all day blat to Le Mans.

I'm much happier now. leaks fixed (although I've still got the two new clips

to fit to the oil filter hose) In the morning I've got 4 wings and the aero

screen to fit then the new tunnel piece and I'll be blatting for the first time

since December 17th. Can't wait as can be seen by the fact that I'm typing this

up at 5:30.

Friday 13th April: It's now 6:30 in the morning. I've just finished

typing up yesterdays joy. It's raining outside (probably inside if I look hard

enough). It was raining yesterday morning but turned out a very nice day by

about 11. lets hope it does the same today.

Now come on, you and I both know, that the day I finish the car and am ready

for the first blat a six week rain will set in!

This may be the last entry in this diary. However somehow I have a feeling

that it may still run for a while.

Get under car to inspect the very nice join in the hose and it's bone dry,

not a drip of oil to be seen. BUT, the clutch slave cylinder is leaking (I

noticed this yesterday but ignored it as if by so doing it would go away). I

will keep it topped up and put it under pressure later. It has only been pressed

3 times since being put back together. I stripped the co-axial slave and fitted

new seals when it was out. The last time I did this it leaked afterwards. The

seals seem to need to have pressure on them to get them to seal. I'll try that,

and if it doesn't stop it I'll change the fluid for something thicker before

taking the engine out!

Right. back to work, only popped in to upload the photos from yesterday.

Finished off the bonnet. Had to make a few more cuts for the exhaust and then made a fill in section on Velcro which is removed when the bonnet is taken off. This is because I've got the rear section of the aperture tucked under number 4 pipe so as to keep the missing part of the bonnet rail as little as possible. Then cut and apply the cool tape to the underside. I've made 3 "pegs" the keep the bonnet in line. 2 are at the rear and the third is by number 4 pipe. A bit more shaping to the air cleaner side and the bonnet's finished.

Bonnet and scuttle in place

Bonnet and scuttle in place

A bloody big hole!

A bloody big hole!

I then spend over an hour sorting the clutch and brake pedal positions and

getting the clutch pedal stop re-aligned by the use of an offset bracket. I

haven't tried it yet but think the travel is now too much for this stop to work.

I'll sort it when all the carbon is done.

Try the MOG front wings. Not impressed. They are too small (13" radius

for 15" wheels) The deep lip is the problem and the wing isn't wide enough.

It will not fit over my tyres. I choose the least scratched old wing and glue

big head fasteners to the new K9 wing I have in stock. I'll have to get MOG to

supply the larger wing. But that can wait.

After lunch I start on the rear wings. I've decided, in the absence of a

rivnut tool, to hold the front section on with heavy duty Velcro.

First job is the get the rear light template in place. It takes me ages until

Lynne walks in to tell me something and I second her to hold the wing. Template

aligned in 30 seconds. She is really marvelous.

Holes for lights cut I fit and glue the lenses into the holes. I'm not sure

this is going to work, but if it does it will look nicer than 6 screws.

Rear lights in place. I'll have my little helper with me tomorrow so I'll get

pictures of the hole cutting process.

Rear lights in place. I'll have my little helper with me tomorrow so I'll get

pictures of the hole cutting process.

Measuring the side panels and drilling the holes is a job for

which my ever loving will be required. I come into to recruit just as she's

laying down for a nap. Like the trooper she is, she gets up and comes and helps.

It takes about 3 hours to get one wing on and that's how far I've got. The

second wing will take about and hour in the morning. Experience is a wonderful

thing.

Rear wing. You'd never guess from the picture that it's held on (at the

front) with Velcro. Seems very shiny!

Rear wing. You'd never guess from the picture that it's held on (at the

front) with Velcro. Seems very shiny!

I said I had a feeling this wouldn't be the last entry. I've been working

really slowly as I'm so knackered I can't work much faster even if I wanted too.

After all this time another day won't hurt and, even though I'm not

superstitious, Friday the 13th wasn't the best day to go for a blat after a

major accident. Saturday 14th sounds so much better.

Saturday 14th April: Started late and things just got slower after

that. I'm feeling really tired and it takes me a lot longer to do everything.

Started by cleaning up. There's bubble wrap and cling film all over the place.

Looks like we've been playing out sexual fantasies in the workshop.

Tools away and bubble wrap tidied up (I need it to rest the bits I'm working

on on) I refit the brake pipe bracket for the rear flexible hose. Not sure if I

owned up to putting it the wrong place. I fitted the bracket above the boot

floor line (placed it from memory rather than positioning the boot floor to

check) So I leave the bracket where it is, it will come in handy as a bungee

fixing point - that's my story and I'm sticking..... Cut and drill a piece of

carbon strip and then drill the chassis. Rivet the carbon a new bracket and the

other end to the chassis. So this car even has carbon instead of metal brackets

- sad?

Now for the tunnel. Problem here is to get the line lock handle neatly

through the tunnel. The lock is fitted about 1.5" below the tunnel top and

I had a large hole cut in the old tunnel so the handle cleared the tunnel. It

didn't look that good. So, thinking cap on I decide to make an extension for the

handle so I have a tube coming up through the tunnel via a small round hole.

Look around for something to make this out of. A piece of copper tube, what a

good idea. The end is formed into a square and then 4 "dots" are

punched in the sides for the screw to hold it down. The other end needs to be

square as well so I cut 6 slots and shape the leaves into a shape that will fit

into the handle.

Right in the middle of this intricate work I'm called for lunch. After lunch

I resume I carry on making my extension. Job done. And it fits. But will it turn

the lock? Try a few times and it seems that as long as I'm gentle it will be OK.

I only use it for hill starts as the car doesn't have a handbrake (other than

for MOT's). In case you're wondering the rear calipers are AP twin pot race

units, much lighter and better than Sierra items. But the AP's don't have

provision for a handbrake. As my chassis is the early one with the handbrake

above the passengers knees it doesn't get used (unless I have a female

passenger).

Call Lynne, who is supposed to be helping me today, to hold the pieces

together whilst I drill a hole. With that done she disappears faster than a duck

running for food. I then start again and drill the hole in the correct place!

Apart from that the tunnel goes on without too much hassle. I have to drill out

the rivets that are holding the tunnel side at the rear as they are holding the

sides too straight making the rear of the tunnel too wide for the tunnel top to

fit. Mark the hole for the line lock handle (and get it right) and rivet the top

in place. I don't like riveting the tunnel top as I have the line lock and brake

pipe unions underneath. The old top was held in place by self tappers but they

come out when screwed into carbon as the carbon "powders" away and the

holes become larger. I'm sure it will be OK, I never needed to get under the top

in the previous 4 years.

I'm still waiting for Lynne to finish whatever women do when you need them to

help on the car. First thing this morning it was a web cam meeting with Malakai,

a regular Saturday morning audience. I wonder if a 7 month old baby understands

that the mad women on the screen is his granny?

So, as I cannot do the wing on my own (well I can but it will take 3 hours as

did yesterdays) I start on the boot lid. A lot of careful filing to get the half

holes (what are half holes called? Half holes I suppose) correct as we want them

as uniform as possible. This isn't really possible with the 4 cuts for the roll

bar uprights as the bar is at an angle and the lid needs to fit over it. It's

very slow work which I'm still doing when friends Pat and Dave arrive. I

make the excuse that I'm just in the middle of doing this intricate cutting and

carry on for a few minutes. My conscience gets the better of me and I put down

the panel and file and join them in the kitchen. I ask Dave how he's feeling and

then wish I hadn't. Dave was diagnosed with a cancerous tumour before Christmas

and has been having Chemo and radiology. Too say he's been a bit rough is like

saying he's a had a bit of a cold! When I try and cheer him up and say that as

soon as the chemo finishes, next week, he'll begin to feel better and get a

whole lecture about how nobody can tell him what will happen as the doctors

can't so.........

OK, they leave and I go back to filing and fitting, filing and fitting, fil...,

you get the idea, it's slow and very boring.

Eventually, at 5pm my lad finds time to join me. The seats are fitted in

record time as Lynne spends 10 minutes doing a seat fixing bolt up with the

ratchet set to undo. The record is the slowest time to fit two seats!

Seats and belts in at last. Lynne made a good job of washing the belts, bless

her.

Seats and belts in at last. Lynne made a good job of washing the belts, bless

her.

We get the template for the rear lights in place and the three

51mm holes cut. These holes then need making larger as the lights are a bit

bigger than 51mm. That doesn't take too long and in about 20 minutes the 3 lamp

holes are cut. Today seems to be full of holes, in tunnel tops, in boot covers,

in the rear wing! Yesterday the same job took about an hour and a half! In the

middle of all this activity Lynne pops back to put dinner on and keeps popping

back to "look at my chicken". Like she's never seen a chicken before!

Getting the wing level

Getting the wing level

Getting the template horizontal.

Getting the template horizontal.

Drill the holes. (In reality the pilot holes are drilled then the template is

removed and the cutter used)

Drill the holes. (In reality the pilot holes are drilled then the template is

removed and the cutter used)

Job done!

Job done!

One happy gnome. Note the black glue all up the arm, and on the hands, and

face and even on my arse. Don't ask how it got there!

One happy gnome. Note the black glue all up the arm, and on the hands, and

face and even on my arse. Don't ask how it got there!

It's too late to start fitting the wing so I decide that we

should glue the aero in place so it can cure overnight then fit the rear wing in

the morning and go for a blat.

Something not seen often. Me polishing. Preparing the scuttle for gluing the

aero on.

Something not seen often. Me polishing. Preparing the scuttle for gluing the

aero on.

Get the aero in place. This is a new design for the carbon scuttle and is

different to the early design which uses the screen fixings to hold it in place.

This is designed to be bonded. We measure it twice and glue once. Richard had

warned me that it might be difficult to bond it without putting a couple of

locating screws in place. It only took 1/2 an hour to get all the glue

off the scuttle and will take it off in the morning to put some locating screws

in place.

Lynne gets dinner ready whilst I start fitting the rubber edging to the boot

lid.

So, still not finished, but, barring major catastrophes, we should be

finished by lunchtime tomorrow. Lynne has promised to help all day.

Sunday 15th April: Get into the workshop about 9:30 and spend an hour

cleaning up from last nights debacle when cleaning the gooey stuff off the

scuttle. Lynne arrives at 10:30 and we get the scuttle off and start marking out

the position for the aero.

The scuttle masked up with old bank statements. If you look very carefully

you can see the pencil marks for where the aero will go.

The scuttle masked up with old bank statements. If you look very carefully

you can see the pencil marks for where the aero will go.

With the scuttle measured for 4 screw holes and then drilled the aero was

positioned and marked for drilling. And then drilled.

With the scuttle measured for 4 screw holes and then drilled the aero was

positioned and marked for drilling. And then drilled.

Having got the scuttle marked and drilled and the aero drilled some black

glue was applied to the aero and then the aero was placed in position. It proved

impossible to get the screws in from the top and in trying the glue was spread

all over the scuttle - again! So clean off glue and start again but converting

the holes in the aero to slots. The screws are fitted from the bottom and the

job is done. clean up the excess glue and then apply some black rubberised

silicone (it came from Superlite and is used to seal the split rim wheels).

I'm not very good at applying silicone from a gun so when we'd cleaned the

stuff up, once more, we have lunch.

It takes but 15 minutes to fit the wing. It would have been quicker if Lynne

had tried putting the first nut on clockwise! "Well, I was using my left

hand". You figure it out. We then fit the boot floor and boot turret

pieces. The car is then dropped to the deck and Lynne slips away for an

afternoon kip. I jack up front and cable tie the front wings on and fit the

Superlites in place of the Revolutions.

Clean up a bit and get in and start up. Bugger it, I can't select reverse as

the clutch stop is not allowing the clutch to be depressed enough. Whip the

bonnet off (joke! it's not easy getting the bonnet off as I've made the exhaust

side a bit tight to clear the exhaust). With clutch stop removed and bonnet back

on I take the car around to the front of the house. Lynne's laying on the

lounger fast asleep and even a few throaty revs doesn't wake her.

I get some tools and fit the piping to the boot lid panels, the grille and

mesh to the nose cone and the two knee panels under the dash. I have used a 4mm

drill for the screw holes and it's not big enough which means I can't get the

screws all the way home. A job that can wait for later. Lynne waked up just in

time to sit in the car and press hard on the footbrake whist I tighten the rear

hub nuts to 150 lb ft. I want to fit the mirrors but get told that Antiques Road

Show is early tonight and dinner will be served soon.

So a quick blat to the village, stop at the bar and show Martine that it is a

real car (she's the new bar keeper and has never seen the car before) and back

home.

I will finish it tomorrow to the point of being able to do a 10 mile blat to

get everything settled and then reset the geometry ane bleed the brakes again on

Tuesday. Wednesday should see a long blat.

At last!

Whilst we were working on the aero in the sunshine just outside the workshop

the ducks joined us. They showed us that old tyres do have a use. As a watering

hole. (more holes!)

Whilst we were working on the aero in the sunshine just outside the workshop

the ducks joined us. They showed us that old tyres do have a use. As a watering

hole. (more holes!)

Did I forget to say that when I applied the line lock when leaving the bar I

forget to be gentle.

Monday 16th April: Just starting at 9:00.

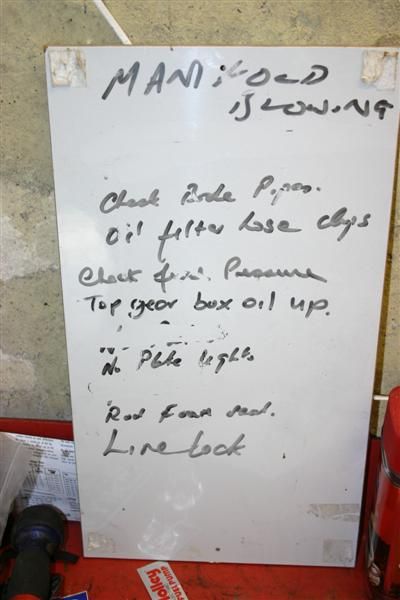

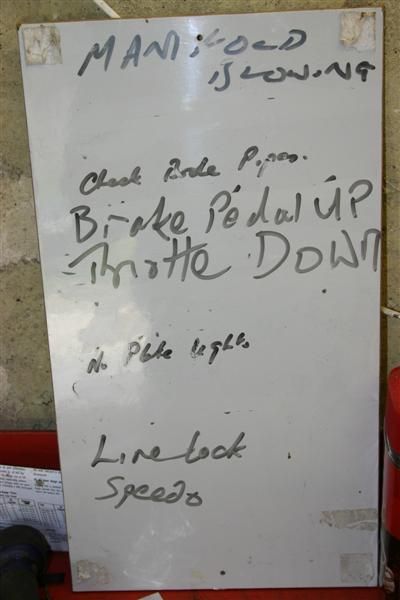

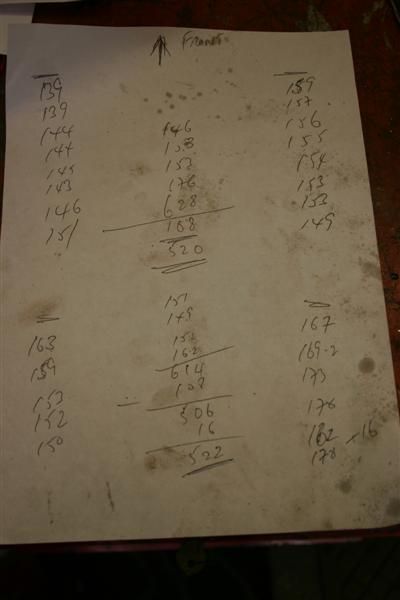

My to do list.

My to do list.

In case you can't read the writing, it says:

-------------------------------------------------------------------------

Manifold blowing. It's a small split in the pipe by the flange (see below)

Check Brake Pipes

Oil Filter Hose Clips - Remember this one.

Check fuel pressure

Top up gear box oil

No. Plate lights. Fit the two led "screw" number

plate lights.

Rad foam seal. Seal the rad between top of rad to nose cone. I

have a roll of foam to do this.

Line Lock. Make a new extension that doesn't break when I

forget to be gentle.

--------------------------------------------------------------------------

I have asked the boy to help fit the mirrors. the reply went something like:

"cough, when I wake up, have had some breakfast, cough, and get dressed,

cough, cough" as she lights the first cigarette of the day.

So I continue with the list. Whilst the gear oil is being fed in I put the

gauge on the fuel filter. 3lbs per square inch - perfect. Oil is now running out

the filler plug so turn the tap off. I use an extension windscreen washer hose

clipped to the plastic 1 litre gear oil bottle and squeeze the bottle with a

ratchet G clamp thingie. To turn the tap off just release the clamp.

Now, nose cone off, 2 little clips to hold the top pegs of the grille and

mesh in and then stick the foam to the rad. I've used double sided sticky tape

and the foam is pipe lagging. Nose cone back on and pop in to get the lad.

Get involved in writing snotty letters to the estate agent whilst Lynne rings

the solicitor. That quick cash deal at £108,000 less the valuations is now into

it's 6th week and I'm fed up with MY estate agent making excuses for the PURCHASER.

I send an email instructing the agent to get it back on the market in Thursdays

property guide.

It's then back to the workshop to get the mirrors on. The lad follows and

then turns round announcing she's got to visit the loo. That's the last I see of

her till after lunch!

I get the car outside and have a good clean up. I go back to the house

promising not to lose my temper and find her on the phone to a mate in the UK.

By the time she hangs up and tells me the gossip 3 times it's lunch time.

After lunch we get the mirrors on. Not bad seeing as it's now 3 pm and we

should have had the mirrors on by 10 this morning.

Now for that blat. The one I've been waiting for for nearly 4 months.

Tomorrow will be 4 months since the accident. get in the car and notice the oil

pressure gauge isn't working. DAMN. Check the fuse and it's blown. The words

that emit from my gob are really unrepeatable!

For the 4th time in two days the scuttle come off and the dash is withdrawn.

The meter shows the live feed to the oil pressure gauge is going to earth. Can't

see anything wrong so remove the gauge and find the bottom of the gauge has the

plastic cut away (to stop it misting up) and is touching the chassis rail which

runs along the bottom of the dash.

Oh well, my fault (like it could be anyone else's!) so just grin and fix it.

Reassemble the dash and scuttle and at 4pm finally set of for the first blat.

Now do you recall I asked you to remember the line on the notice board

"Oil Filter Hose Clips"?

Well do you also remember it's brother, that "bloody join" that was

also leaking? The bloody join is now promoted, the new "bloody hose"

is the oil filter one which came adrift 5 kilometers from home and dumped £40

of Mobil One on the road!

Luckily (where's the bloody luck in this story!) the big red oil pressure

warning light worked. I cut the ignition as soon as it came on, about 3 feet

after the oil trail stopped. My mobile phone has no money in it, but that's

another story which I may remember to moan about later. I walked up to a house

with the door open and asked if I could use the phone. "Lynne come and get

me" I felt the panic coming down the phone line. I've not had an accident,

dear, I've broken down. I'm at Chappele Hullin. We've lived here 15 months, this

village is 5 kilometers from the farm. It may as well be on the moon. Lynne has

no idea where it is. I give directions and 10 minutes later up she rolls.

We get the rope on and I give instructions how to tow. She passes 9 out of 10

which isn't bad for the first time she's towed. No, it's not "isn't

bad" it's bloody marvelous! We get home, remove the rope, push the car into

the workshop, get the ducks in and feed the cats and then get in the Elise to

visit the bar. I need a drink!

Lynne says the bar is closed on Mondays. I say it's open. We get to the bar,

turn around and come home. I open a bottle of Stella and am typing this up now.

I'll do the blat in the morning, after reconnecting the oil pipe with the new

hose clips, and then get back, wash and photograph it.

The manifold. One of the welds on the pipe to flange has fractured. I was MIG

welding it when I ran out of gas. I've now got the gas but forget to complete

the weld. It'll only take an hour the get the pipe off, finish the weld and

replace. But it can bloody well wait for now.

In the meantime I've been asked to add this little missive from the lad.

MY TWO REBUILDS

Let me start by saying my rebuild started about eight weeks before Normans.

(following his accident) I had a larger body to deal with and my

body HAD A MOUTH, and boy oh boy if you have ever heard the roar of a good

engine, trust me, mine growled louder, and pumped out verbally more oily abuse

than you have every heard. As there was no carbon in sight this body is very

heavy!!! After getting over the initial shock, I then settled down to the task

of being the “lad”. Norman was stuck in the chair for nearly

seven and half weeks (a lifetime trust me). The first morning to me

will always be the funniest. During the night he must have slipped down

the chair. He then asked for assistance in getting upright – nice

thought – bad move!!!! We did ½” in 10 minutes.

If I explain at this point that my patience level is zero – I pleaded that he

tried a little harder.

He did, and we managed another ½” in the next twenty minutes. Ok

so progress was slow, my patience failing and my patient getting madder.

We needed to rest he said. So we rested. On the next command,

we tried again. Wow a whole ¾” progress was being made. After

about an hour and a half we had gained about 2” in coming forward.

It’s a this point he announced we have a problem. WE need to

pee……… I said, being the logical woman, that at the rate we were going

could he hold on for another four hours. NO was the reply. Ok

– so I look around – erm something to go in me thinks. I

go in the kitchen, sitting nicely in its tall jar is my plant……..oh well –

plant dislodged from jar, jar taken into the lounge, “get it out” I said

with smile on my face and lets get this job done.

Success, patient smiling and we start again. Four hours later he’s

sitting up from which position he can stand.

It took me eight weeks to get my body up and running (I’m new at this rebuild

lark)!!!!!

Just when I thought the rebuild was over……….The Body spoke again….

We’re (the Royal “we” I take it) are going to re- build my car.

Now I know nothing about cars, and those that know me are aware that I will

follow Norman to the end of the earth – but – in MY car.

If I have learned anything during this rebuild its that I can be praised, loved,

hated, yelled at, abused, all in the space of three minutes.

Apparently that’s called the joys of owning a seven. When the

MOUTH says “dearest” he wants me to do something – when it says

“you’ve done a wonderful job today” its means YOUR GONNA HELP TOMORROW!!!!

I have learned the names of car parts, tools and what bits go where. I have my

own names for all the tools and many names for Norman (mostly unprintable).

I must admit there have been times when I have actually enjoyed helping (DON’T

TELL THE NORM) and other times when I’ve wished the bloody thing would just go

away.

Yesterday when I woke up from my Sunday afternoon nap and the first thing I saw

was the 7 standing proudly outside the front door – two things went through my

mind.

The first thought was, yep it looks good and thank goodness its finished.

And the second was – I’m still not impressed.

NOW the worrying thing is.....

WHAT'S HE GONNA THINK OF NEXT!!!!!!!!!

So for me – it’s the end of TWO RE-BUILDS, and now both of them have

shiny new bodies, both still roar like hell……………………and hopefully

I will have them both around for a long time to come – well the car needs

someone to play with!!

Signed: THE BOY

Well she wasn't finished, she now knows how to tow.

Tuesday 17th April:

Today she got 10 out of 10.

Started by jacking the car up and removing the hose clips from the filter out

let hose and fitting 2 new ones. Something I should have done before blatting!

Changing the hose clips didn't take long, cleaning the oil of the chassis and

floor took longer! I'm becoming a polisher and, if it persists, you have my

permission to put me out of my misery.

All the oil cleaned up it's time to top up.

Get a can with about 2 litres of Mobil One 15w/50 and dump that in. Then open

a new 5 litre can and start pouring it in. Funny its taking a lot and no oil on

the sight glass yet. Then the oil in the funnel stops at the rim and I realise

that the oil is so clean I haven't seen it in the tube. The tank is full and

overflowing! More oil to clean up, what a pillock! Get the sucker out and drain

the tank back to the full mark. Clean up the spilt oil.

Coming up for 12:00 so I go to the shop for breads (we have to have a full

cut loaf for the ducks - I get a bit of baguette!). I then pop round to the Ford

garage to get two more clips. I need one more because I stripped the worm on the

second clip. I thought no one would notice my mistake if I put it here instead

of above.

The wife of the owner was on her own, the garage being shut for lunch,. So I

took her into the parts department and got two jubilee clips. Sounds good, but that's

it - two hose clips.

Having paid her, we went outside and started inspecting the car. Whilst

carrying out this inspection, her son drives up. He is an apprentice at the

Peugeot garage in the next main town, Segre. We spent more time walking

around the car and discussing carbon.

Right, lunch out the way, I'm off for that 20 mile blat. Up to Vergonnes,

turn right and then left to Chappele Hullin. This is where the oil pipe came off

yesterday and it's nice to go through the village with 4 bar oil pressure. On to

Reneze. As I turn left toward the main road the car start coughing. and

spluttering. And another cough. And silence.

No Petrol! Never mind, it's not far to the petrol station. Off I walk and

having walked around the super market looking for a petrol can the man behind

the fish counter asks what I'm looking for.

I make the shape of an oblong can with my hands and explain "Mois Françoise

petit pue, pour le essence" "ah, Oui, jerry can" was the

response. Now why didn't I think of that! They don't have one. But all is not

lost as next door is a small Brico Marche and they have one.

A gallon, sorry cinque litres, of fuel and way she fires. I fill up and carry

on my blat. Turn left to Congrier and then continue to St Aignan-sur-Roe. bear

right towards Croan.

About a mile along this road the big red light comes on and Lynne gets to

score 10/10!

This time the bloody oil filter hose at the other end has come off. It was

held on with one of those fancy anodised hose clips. Useless!

It shouldn't be hanging around like this, should it?

It shouldn't be hanging around like this, should it?

It only take 10 minutes to get some decent clips on it, whilst

Lynne pops round to the garage to get some more just in case.

4 new clips alongside a chocolate fireguard

4 new clips alongside a chocolate fireguard

Clips changed but this time the oil is everwhere. all along the body and

wing, the floor, under the rear wing, all over the rear suspension.

Having cleaned up again I get the car outside and wash it with warm soapy

water. Lynne helps and we get it ready for the photo shoot.

But, she says she's has enough for one day, towing is a very stressful job.

We must go to the bar!

No arguments there, so an hour later and 4 1664's I'm ready to take some photos whilst Lynne prepares dinner.

Had I had more time I would have cut the grass. I thought that two days

promise finally fulfilled no one would mind long grass.

The plans for tomorrow are to get two large floorboards into the workshop,

get them level and do a full flat floor set up.

There are still some bits and pieces to do....

The new carbon boot cover. I've yet to fit the roll bar sealers and glue on

the rubber surround trims

The new carbon boot cover. I've yet to fit the roll bar sealers and glue on

the rubber surround trims

... as soon as one thing get rubbed off two more appear!

... as soon as one thing get rubbed off two more appear!

Wednesday 18th April: It struck me after doing last night update that,

on the 40th anniversary of the Torry Canyon (today is 40 years plus 1 month)

that I've dumped more oil in two days than it did!

8am here, so breakfast and get those floorboards into the workshop and

levelled up for a flat floor session.

The floorboards are 2.7 x 2.0 meters. In my weakened state I have no chance

of getting two of these into the workshop (from the long barn).

I first roll the 7 backwards out of the workshop and it come to rest in the

middle of grass area in front of the workshop.

So, put the thinking cap on and get the spirit level out. The working area is

way out, it runs downhill. The centre bit, where the drive in is is much better

but still running downhill. I get the "Battered Old Super Sport" out

from the other end. This is a 7 owned by a friend which he has for sale. I'm

looking after it as he's moved back to the UK. The battery is flat so I push it

out. The floor at this end is level. So I get the broom out and give it a

good sweep.

Jump in my Seven and start it. push the clutch down and it dumps all the

clutch hydraulics onto the grass.

"Lynne, come and pump the clutch pedal - darling". She not

dressed, has on a flimsy nightdress only. Sorry lads - no pictures. She climbs

in and lets out an ear piercing scream. "What's the matter", says a

very concerned hubby. "These seats are cold on my bum" Women!

Clutch bled and master cylinder topped to brim to keep an eye on the level I

drive the car onto it's flat floor.

I have 3 bags of cement, each weighing 36 kilos which are placed on the

drivers seat to act as me.

The likeness is uncanny.

The likeness is uncanny.

Check the track first and spend some time getting it spot on. Then check the

camber and decide to adjust the o/s. It's within tolerance but could do with

another half degree. So give the top joint two turns in, refit it and check

again. Could do with another turn so undo the top joint, one more turn and

refit. Spot on.

This adjustment has, of course put the track out. So it's another 1/2 hour trying to read 2mm off the rule. Even with my glasses I find this difficult.

Not easy to see but the fine twine "box" around the car is the way

I check the track. You can just see (if you have excellent vision) the camber

gauge leaning up against the front wheel.

Not easy to see but the fine twine "box" around the car is the way

I check the track. You can just see (if you have excellent vision) the camber

gauge leaning up against the front wheel.

Lunch. Doesn't time fly.

I have cut 2 pieces of stiff cardboard 125mm and 140mm. With these I set the

ride height. It takes best part of an hour to get the heights at each corner

more or less right.

Now get the four bathroom scales out and under the wheels. Not too bad. Needs

a bit of transference from o/s/f to n/s/f.

The weights as I adjusted them. Comments on a postcard please.

The weights as I adjusted them. Comments on a postcard please.

I'm a bit disappointed about the total weight. The car weighed 520 kilos

before the rebuild. The chassis repair meant that the chassis weighed a bit more

than before and I must have put a kilo of paint on. Against this must be set the

saving of carbon over aluminum. However it weighs 520 kilos so no saving at all.

I was hoping to get it down to 500.

We have friends coming round tonight so I have to pack up early. I get the

car out of its flat floor area and start doing some quick jobs, the sort you can

leave at a moments notice. Stick the badge on the nosecone. Deal with the edge

of the n/s front panel. They still haven't arrived and I'm not getting nagged to

get showered and changed so I start making the line lock handle extension. Cut 2

pieces of right angle, file the insides square and braze them together to make

the square. Then braze a thick washer over one end for the retaining screw. At

this point I hear a car drive in. Tom and Carol walk round to the house and I

start packing up. Then Tom come into the workshop apologising as he didn't

realise I was in there. "You usually have the radio blaring out so I

thought you were in the house".

We stood there talking cars and bikes (he's a biker) for about an hour. The

girls were sat in the evening sunshine outside the house demolishing a bottle of

red. We joined them and sat outside whilst the sun set, a huge red ball. This

world can be a perfect place sometime, when it's not covered in oil!

Thursday 19th April: Having just finished typing up yesterdays going

on's I'm off to the workshop to finish making the extension. We are taking the

Pug for it's Controle Technique at 11. (French MOT). If it gets through then we

can then go to the Sous Prefecture in Segre and get it's French

Registration. I can also pick up my French driving licence. However I doubt it

will pass first time. It seems that over here you get 2 months to get a failed

CT fixed - and you can drive the car on the road in that time! And the CT is for

two years.

Cut a piece of rod from the old, damaged lower wishbone. This must be the

first time in history that something one keeps 2because it may come in

handy" actually does! Having then brazed the rod to the washer I grind a

5/16" UNF nut to a square, then braze that to a washer and the the washer

to the rod.

Fit the new extension and handle.

Red insulation tape around the extension.

Red insulation tape around the extension.

Jump in the car. DAMN! The clutch fluid has drained out again. Right, now I'm

mad. I refill with hydraulic oil and the boy helps me bleed it, hopefully for

the last time.

Still an hour before we go to get the Pug tested so I decide to fit the

number plate lamps. I've had these, US Hot Rod number plate "screws",

which are led lamps for about 5 years now. I drill the rear wing and screw in

the screws. Then go to fit the LED's into the screws and find that one of the

wires has come away from the LED bulb. Try to solder it back on but it's too

fine for my tip and I fu, erm, that it - FU it. So now I've got two holes in the

wing, two screw heads in the holes but no lights to put in them because I've

broken a wire off the second lamp!

I'll have to search the web tonight for replacements.

Off too town for the Pugs CT. I go in the 7, Lynne drives the PUG. We get

there and he asks us to come back at 12:00. Lynne thinks it'll be a good idea to

pop back into the town centre and walk around the Thursday market. So we both

get in the 7 and drive back into town. Park the car outside the doctors and

visit Mr Ed the small supermarket. Put the shopping in the boot and then walk

around the market. I'm fascinated by the two wet fish stalls. Full of lovely

fish and sea food. Whilst I drool Lynne's looking at the cl;othes stalls.

"Lynne, it's nearly 12:00, we'd better go". She looks up and walks

back towards the car. Phew, that was close, I can hear my wallet breath a sigh

of relief!

The Pug's failed but only on the rear brake efficiency. He suggests I clean

the dust from the rear drums. We pay and set off home.

Get back home and get the wheels and drums off the Pug, blow the dust out and

roughen the shoes and refit drums and wheels. I earnt bonus on that job.

We have lunch whilst I go into one of the stupid estate agent. After

lunch I set about cleaning the seven, which is now full of dust and cow shit in

preparation for another photo shoot after I have cut the grass.

Whilst washing the bonnet Lynne comes round with the phone - its the stupid

estate agent. Whilst Im ranting at the poor girl the soap dries on the

bonnet which is in very hot sunshine. The white milky stain takes an hour

to get off.

I cut the grass in front of the Gite, place the car in the middle and spend the next hour and a half taking about 70 photos.

During the photo shoot I hear the phone ringing. Can I find the

bloody thing, I'm running round the field trying to locate the sound of a

ringing phone, which of course, eventually stops.

Then, the camera decides to pack it in.

I really go into one now, its that last straw. Lynne diplomatically

suggests a nice cup of tea. That calms me down and I realise that the

camera strap is wrapped around the built in flash which, for some reason, wants

to arise. It cant get any brighter than it is today but my camera thinks it

needs a flash for a picture of a car that is about 100 yards away. Oh for my old

non computerised Pentax.

Photos taken I come inside to download them. Whilst there downloading I

get changed in readiness to return with the Pug for retest. If I get it

back today there will be no extra charge. I like that.

On the way I fill up with petrol and pop into the supermarket for a tube of

superglue to glue the rubber trims on.

Jacky, the tester finishes the test he is doing and then puts the Pug on the

brake tester. It gives the same readings as it did this morning.

I point out that the car has a load sensitive brake limiting valve. He

gives me a sheepish grin, which, I suppose is better than a Gaulic shrug!

I have had several enquiries about the carbon boot cover so these two pictures should answer everyone's questions including Harry Flatters.

The carbon boot lid is made of three sections, two ends and a centre. All

three sections have a deep lip which will cover the studs for the hood.

The carbon boot lid is made of three sections, two ends and a centre. All

three sections have a deep lip which will cover the studs for the hood.

The boot lid.

The boot lid.

The end sections "hinge" on the cut out for the roll bar and swing

away from the centre like this. With both ends off the centre will come out,

however for most requirements taking one end off is sufficient. I've put Velcro

all around the four edges of the boot aperture. However, with careful shaping of

the cut outs the covers are tight enough to have a couple of Velcro tabs to hold

them in place. Richard is making seals for the two half holes for the roll bar.

The cover not only looks fantastic but should be waterproof.

Time for dinner during which I rant about the estate agent and get Lynne

upset (nothing new there then). I then go outside and wash the battered

old super sport.

The local Ford garage, who looks after a few Caterhams in the area, seems to

have been telling everyone about my car as I get an email from a couple who run

a garage in Angers which specialises in sevens as well as more exotic machinery

such as Porches and Ferraris. I have made arrangements to go and visit on

Monday morning. I wonder whether I will get back on my own steam (the boy

says she ain't coming this time).

Tomorrow I have the break pipes to check, a new oil pipe to fit between

filter and pump and I'm going to screw the front edges of the rear wings.

The Velcro is holding them fine but the rattling is driving me mad.

So as its nearly finished I thought I would leave you with this....

It was at this point after two hours of typing and uploading pictures that

the one and one website acted like I have been doing all day long, threw its

toys out of the pram, shouted a few swear words and refused to do anything else.

So I have got Lynne re-typing all this as I dictate. I've always wanted to

be a dictator.

THE LIGHT BULB HAS JUST COME ON. I have just

realised that the 520 kilos weight of the car is with a full tank. The

previous 520 kilos was with a half tank. I've calculated that 35 litres of

petrol weighs 25 kilos so half of that is 12.5 kilos.

Therefore the car weighs, on a like for like basis 508.5 kilos. That's good.

Friday 20th April: I get up early and spend two hours doing copying

and post. Also search the web for new number plate lights. Find them on Ebay and

click "buy it now". I follow the instructions (never bought from ebay

before) and have to send an email to the seller to let me know the postage cost

to France. During the day I've had 4 different emails telling me how lucky I am

to "win" the item on Ebay. I still haven't got the post costs.

We set off to the sous prefecture in Segre armed with all the documents to

get the Pug a French registration and me a French driving licence. Pop into the

garage in the village to pick up the new battery for the Battered Old Super

Sport (BOSS). It's there by the side of three bottles of acid. So I ask him to

fill the battery and charge it Si Vous Plese (or however it's spelt). Then off

down the road to the post office to post several letters and send the box with 2

wings back to MOG. (They have sent 15" wide ones). When we come out the

post office I notice 2 or 3 drops of oil under the car.

Back home I drive the car into the workshop and jack it up. The hose, which

I'm going to replace, is leaking at the oil pump end.

Leave the 7 in the workshop and set of for Segre in the Elise. No queue at

the sous prefecture (I like the sound of that). Hand over all the paperwork and

the very nice lady, who speaks a bit of English, starts going through it

all. I then request the Permit de Conduit (Driving Licence) and we get more

forms.

We leave with a long list of more paper to obtain before we can move on. I'm

not surprised that French companies dominate the paper industry, they have a

home grown head start!

So, SAE, stamp, name and address of the person I bought the car from and his

signature on the bottom of the form, 2 passport photos, my passport, 2 utility

bills and probably another 6 things that I've forgotten about. All this is

required for 3pm.

We decide to have lunch at one of the bars in Segre centre. Very nice sitting

in the blazing hot sun having a cool beer, omelette and chips. We set of home

and I plan to fix the oil leak and return with all the paperwork when they open

after lunch at 3pm. Get two new hose clips on the pipe and tighten them. It

still drips so tighten a bit more. The hose clips strip.

We return to Segre in the Elise. We stop of on the way to get some better

hose clips and some passport photos. We then stop at the Poste to get a stamp.

As Lynne walks back across the road to the car I can't help but think what a

cracking bird I married. She looks really good with her cap at a jaunty angle,

her new jeans and summer blouse. Pity I didn't have the camera with me.

It takes half hour to get everything sorted. The new registration card (carte

Grise - Grey card) should be with us in 15 days. Apparently, the prefecture will

visit my house and then I have to go to Angers to collect my new driving

licence!

We get back home and I fit the hose clips, start up and run it for 20

minutes. No drips. The remove the seats and drill through to fit a screw to the

wing. I make a penny size hole in the inner panel to get the washer and nut on.

This will be covered by a rubber plug. I also fit some spacers on the rear bolts

to my seat so I can see over the aero.

All that done, I fit the battery to BOSS, get it out and take some more

photos. I washed it yesterday so it looks much better now. If any one wants a

cheap Super Sport contact me.

BOSS, a Super Sport looking for a new home.

BOSS, a Super Sport looking for a new home.

I drive my car up the drive as Lynne comes running after me to tell me tea is

on the table. She thought I was going out whereas I was only going to the top

and back to try the seat position.

Tomorrow I'm going to drive the car around the "block", about 3

miles, for an hour or so. Then I'll closely inspect the oil hoses to make sure I

have no drips, that is apart from this one! Then if I break

down I've only 1.5 miles at worst to walk home.

Saturday 22nd April: Drive the car around the block once. how boring!

Spend the rest of the day sunbathing. I'm now very brown, and it's not rust.

When it cools down I ask Lynne to help me adjust the clutch pedal stop. I'm

sitting in the car and Lynne's turning the screw (she's very good at turning the

screw).

We hear this very loud buzzing noise. It's like a wasp's buzz but much deeper

and louder. Then a thunk! "What the f..k was that!", "I don't

know" says I. I wait while looking around the floor and in the tool box

tops. Nothing. So we carry on. Then a buzz, buzz. I look up and Lynne, who is

now sitting in the car says that it's fallen on the bench. Buzz, Buzz. I'm not

sure I should get too close. Then it flys up from the bench. It looks like a

miniature helicopter and is HUGE. It must be stunned from flying into the wall

because it again falls to the work bench. It has landed upside down and I can

now see it's a huge beetle. It has a headache, or is drunk, because it's on

it's back going round and round.

Sorry, but whack goes the hammer and I throw the remains outside.

Finish adjusting the clutch stop and refit the bonnet.

Sunday 22nd April: I do another check for oil leaks and then drive twice

around "the block" about 6 miles. Have lunch and we set off to the

Brits St Georges day party. They have stalls flogging stuff and a bar with

Speckled Hen in cans. Then I spot some cars, an Elan, a Morgan and a Roller.

Walk over and get talking to the owner of the Elan. I've met him before and he's

a fanatical Lotus chappie. He suggests I bring the 7 in. When I get it parked up

next to the Roller I begin to regret it. there is a huge crowd, with kids

climbing all over and in it!

Then the adults start climbing in to see what it's like to sit a Course de

Voiture (racing car). I give up and go and get another beer.

The drive there and back takes place in about 90 degrees heat. The temperature

never goes above 90 and drops to 75-80 when moving forward. I'm pleased about

that, it looks like I may get away without having to cut a ventilation hole in

the bonnet.

We set off home about 5pm and drop Tom & Carol off (Tom has been my

passenger, I hope I didn't frighten him too much).

When I get home I need to do 2 things. The mark 533 (or whatever) throttle

pedal has failed, it's worked lose and the pedal is at 90 degrees to my tootsie.

I also need to pull the steering column up a bit as my big fat knuckles are

kitting the switches.

Raise the column, remove the throttle pedal and scrap it. make a new pedal by

brazing mild steel pieces on instead of screwed ali strips. It fits OK first

time. I'll tidy it up a bit later by raising the angle slightly and screwing in

the adjustable pedal bit.

So two trips out, 6 miles and about 30 miles and get back without a drop

of oil being spilled.

I'm off to Angers tomorrow, that should be fun.

Oh, I forgot about the tantrum with hammer. A hammer gets stuck, handle up,

with the draw above it partly out. You try and get it out without losing your

temper and screaming at it, Basil Fawlty style.

I couldn't.

Monday 23rd April: Go to a village near Angers (60 kms each way! Wow)

to visit a garage who have contacted me and would like to see the car. They

prepare race cars.

I get there at 10:30 and they are very busy with paperwork (they are French

after all) and ringing telephones. (one of my favourite lines from a Joni

Mitchell song is "tethered to a ringing telephone").

So I have a look around. There are 2 Exiges, an Elise, Porsche 911 (old one)

and a Donkervort in the workshop. Parked outside is a single seater formula

Renault. In other parts of the building are more Porches and a Lancia

Integralle.

I always pride myself on being observant.

Sylvia then gets out the office and puts on her tour guide hat.

I missed to dust free engine assembly room and, even worse, behind a

soundproof sliding door a 4 wheel drive rolling road!

She apologises for being busy and answers yet another phone call. I go and

wait outside in the blazing sun. A chap is now standing outside and he asks me

(in very good English) if the Caterham is mine. We start talking about cars

(what else). A Transit van with a trailer and a moto cross thingie on the back

is reversing in. It's the chap from the Ford garage in my village, Noellet!

We then spend 10 minutes passing the time of day having all shaken hands and

wished each other Bonjour. How nice.

Having left the buggy thing he goes. I continue to talk to the French chap.

After an half hour he mentions that he's waiting for them to finish his race

Exige. He then hands me his business card. He is Laurent Sauzaeu, a leading

light in Club Lotus France and the MMA Insurance agent in Nantes. Although we've

never met we know of each other as he tried to get me cover on the 7 when we

first moved here.

Then a Pistachio over white Lotus Elan (circa 1968) drives in. It is followed

by a lady in an Audi TT. The lady (I assume wife but in France it could be the

mistress) join Laurent and I. She is knowledgeable about all things Lotus and it

turns out they are the couple with a 7 who's picture is above the reception area

in the Ford Garage. They know of me and I know of them. We've now met.

This is getting scary.

!2:00 and Laurent's car is ready and after some more chat about his race

helmet (the one he puts on his head) and it's "LOTUS" logo he leaves

for Le Mans. I then decide I may as well go, The Elan couple have also left, in

the TT.

Sylvia is very apologetic and asks me to wait and we will all go to lunch

together.

I'm getting to really like this French way of life. We go to a little cafe

down the road and spend a very pleasant hour and a half having a drink at the

bar followed by a 4 course lunch. Isn't that nice?

When we get back we spend an hour or so discussing products they want to be

dealers/distributors for. They have noticed that there is no race component

industry in France, everyone gets their stuff from Germany or the UK.

Anyway at 3pm I take my leave and have a fast drive back.

And I never broke down but have a small oil leak from the lower sight glass

union in the dry sump tank. Won't take long to fix that.

Today's list is therefore,

Oil Leak, fuel gauge (erratic), fan switch (erratic and probably to do, I was

going to say "connected", with the fuel gauge), and to tighten the

n/s/f brake pipe which is weeping.

Tuesday 24th April: The internet is down - again. Lynne tries to get

France Telecom on the phone but there's one bit on the menu she doesn't

understand. She thinks she's being told a number to phone but can't get it down

as the recording is too fast. In the meantime I go into the workshop. I do the

four things on the list. Drain oil tank, remove, split, tighten sight glass ends

and put the two halves back then refit. Remove dash and wiggle some wires. Can't

see anything wrong so put it all back. The near side front brake pipe has a

partly stripped thread in the caliper. Fit a thick fibre washer and retighten.

That's done it. Bleed brakes (Lynne is remarkably helpful) and push very hard on

the pedal. Not a weep in sight. All jobs done.

In the evening we pick up Tom and Carol, Tom in the Seven, Carol with Lynne

in the Pug and go to some friends for a jigsaw puzzle evening. A fair size group

are outside talking and drinking. On the way back I notice that the water temperature

gauge light isn't. Isn't lighting the gauge that is. Another job on the list.

Wednesday 25th April: Lynne pops into town while I try and sort out

the sale of the house near Sheffield. The post girl comes whilst I'm on the

phone and leave a card that there's a parcel to sign for.

By the time Lynne gets back it's nearly lunch so I have lunch. Lynne asks

Debbie (who speaks French fluently) to ring the service number and tell her the

missing link. All it is asking is for her to key in the number that has a

fault! Eventually she get through to someone. "parlez vous Francais,